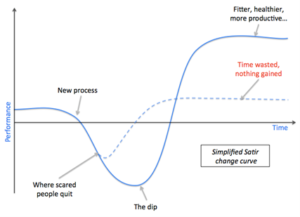

With any meaningful change, things get worse before they get better.

That’s it. That’s the reason so many companies get stuck, especially on the road to digital industry transformation.

The Productivity Dip

Simply put, a company will experience a Productivity Dip when it implements any new technology or workflow. Many companies will either avoid making meaningful changes to avoid this dip or, worse yet, begin a change and then abandon it when this dip occurs.

We see it every day. Companies are hesitant to change solutions and workflows, even when doing so will bring transformational change. Why? Because all they can see is the temporary pain associated with the Productivity Dip. This pain can come from areas like:

- -Retraining employees

- -Getting buy-in for the change

- -Financially surviving the temporary dip in productivity

- -Bringing a new workflow to maturity

Without question, factors like these will bring temporary pain. And for businesses that are surviving month-to-month just to meet their delivery schedule, any meaningful change can feel impossible.

But what remains true is that any meaningful change will involve temporary pain. If there’s no temporary pain, chances are the change isn’t a meaningful one.

What to Do?

The question then becomes: how do you accelerate and de-risk the Productivity Dip?

Answer: find trusted partners to help you make it safely to the other side of that temporary pain — to the place of mature workflows and solution mastery.

Digital Transformation for Companies Big and Small

We’ve seen these types of transformations across many industries, and not only at the level of large businesses. We’ve seen businesses of 10 to 200 people fully switch their CAD software with incredible success. We’ve seen companies link all their design and engineering practices using the digital threads that connect all solutions within the Siemens Xcelerator Portfolio. We’ve seen full real-time associativity between design, engineering, and manufacturing teams so that all product models are updated in real time across all silos.

It’s happening. Small and medium-sized businesses are thinking beyond temporary pain and fulfilling the vision of the modern digital enterprise. And they’re doing it by establishing clear digital threads between all their departments and the digital tools they use.

Mechanical and product designers can work from the same live designs as their colleagues working on the shop floor with fool-proof revision management. CAE engineers can join in the effort and have their models instantly updated when a CAD team member makes a design change. Automation process designers can pull full kinematic models from their mechanical design teams with zero data loss, and controls team members can run their hardware into a computer and validate their code against these models as though they were real equipment. Operations managers can even use full digital twins of facilities to simulate “What-If” scenarios and endlessly refine their production processes. The possibilities are endless.

Your Next Step in Digital Industry

The potential of the digital enterprise is being realized more every day by companies willing to look beyond temporary pain and build true digital threads uniting their design, engineering, production, and operations teams.

To learn more, please don’t hesitate to reach out to us at Longterm Technology Services. We’re here to listen to your ideas and discuss the endless possibilities that digital transformation can bring to your company.