Manufacturing Setup Automation

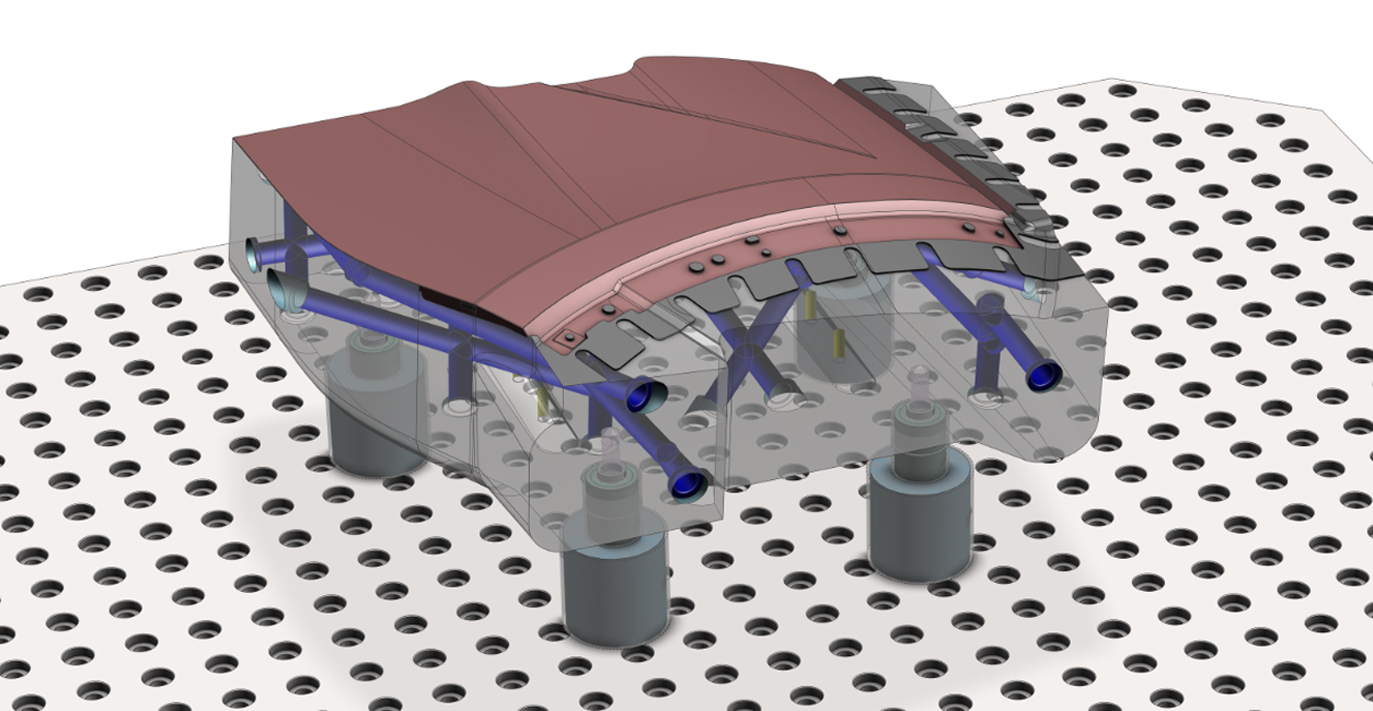

Modular Fixture Designer (MFD)

Modular Fixture Designer (MFD) is a state-of-the-art solution for manufacturing setup automation. Automate the stack-up process with intelligent selection strategies for various setup components. Work within one solution: Siemens NX™ to complete the entire process without any need of data translation.

Fixture system is a set of devices to securely hold the position of workpiece during machining process. Modularized fixture system is a high-performance solution, especially for mold manufactures.

Keeping user benefits in mind, we have also partnered with FCS System, who is a renowned industry leader.

Modular Fixture Designer (PDF) >

Do you struggle with any of these challenges?

– Difficulty finding optimum combination of manufacturing setup components

– Lost accuracy and degraded efficiency due to undesired number of setups

– Having to leave native software platform to find setup solutions

– Deal with data translation issues for forced data migration

– Hard to visualize chosen setup components

– Tedious to locate correct seat hole position for the setup device

– Cumbersome process for managing setup library components

– Manually creating setup reports for shop floor

If yes, then we have a unique solution to address your challenges:

User Benefits

Easily identify best seat hole positions for setup component

Use optimized system generated component combinations

Need significantly less number of setups than conventional methods

Improves repeatability and productivity

Work within the already familiar Siemens NX software system

No hassle of data translation

Easily choose desired component position with the projected grid points

Choose components from the expanding FCS component portfolio

Easily generate customized setup reports

Business Benefits

Increases Profits

High ROI

Eliminates Errors

Improves Quality

Improves Lead Time

Provides Competitive Edge

Quick Implementation

Requires Limited Training

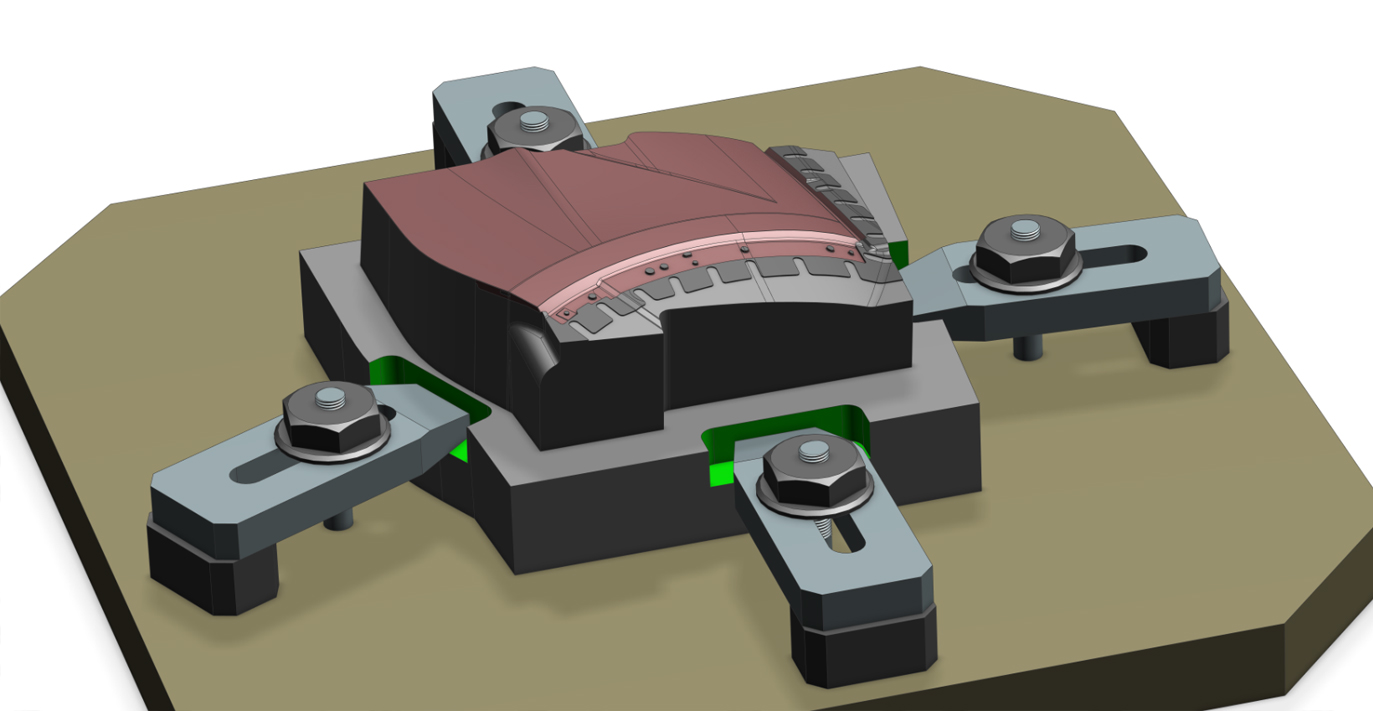

Modular Fixture Advantages

Access up to 5 faces on the workpiece without restrictions

Reduce number of setups

Easily remove and assemble workpiece while maintaining the zero reference point

Quickly clamp at original zero reference point during engineering changes or reworks

Position workpiece for best machining chip removal

Optimize machine workload

Use during complete production cycle from design to try outs

MFD Advantages

Visually find positioning opportunities for setup components using projected grid

Data translation not required

Ideal for Siemens NX users

Obtain optimum combination of setup components

Easily manage multiple manufacturing setups

Verify for potential interference results for selected configuration

Generate setup reports for shop floor

Standard Fixture

Modular MFD Fixture