Imagine streamlining your entire part manufacturing process by using a single, comprehensive CAM software. Automate NC programming, accelerate machining, and achieve high accuracy using advanced toolpath technologies and integrated G-code-driven simulation.

Reach out to our team of experts to discuss your unique needs and goals. We’re excited to show you how NX CAM will revolutionize your manufacturing workflows and bring your boldest ideas to life.

The Problem

Speed and quality are everything for today’s machine shops, even as customers demand increasingly complex products. Your company needs to generate paths that spend more time cutting material and less time cutting air. You need feature-based machining to automate the generate of cutting paths from CAD designs, and you need high-speed roughing, semi-finishing, and finishing to get the job done better and faster. You also need to simulate your machining using real g-code to make sure everything runs as expected for maximum quality.

That’s where NX CAM comes in.

The Solution

Imagine a single CAM program that handles all your machining operations, reads the design intent from your CAD, and automatically generates reliable cutting paths.

Learn more about how the benefits of NX CAM will touch every aspect of your machining workflow.

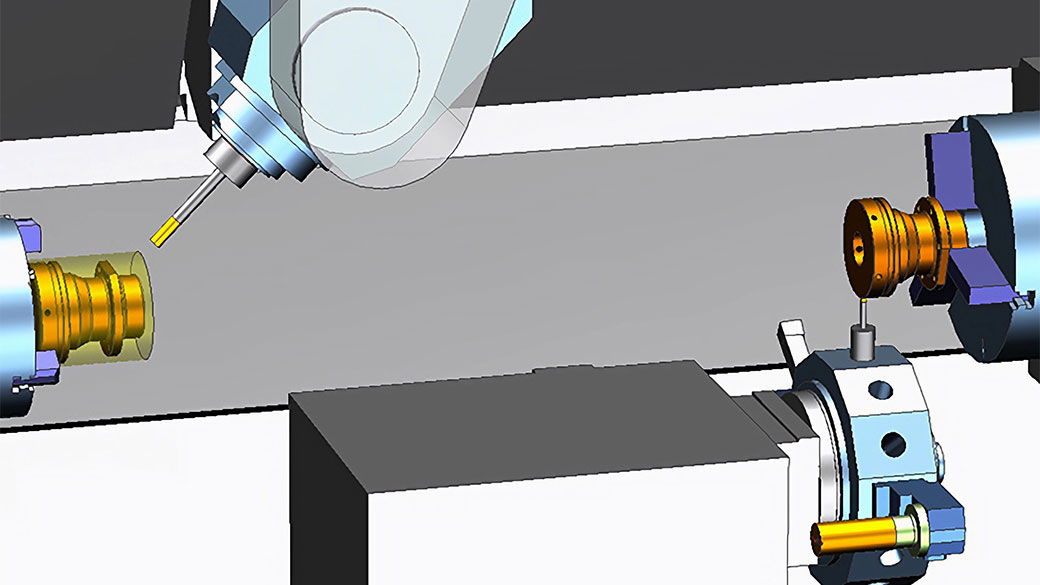

Prismatic parts machining

Rapidly program prismatic parts using advanced 2.5-axis milling and turning technologies.

Volume-based milling, automated feature-based machining, and interactive mill-turn programming capabilities can help you simplify prismatic programming.

Imagine using automated capabilities to reduce programming time by up to 90% while generating optimized machining operations for high-precision components.

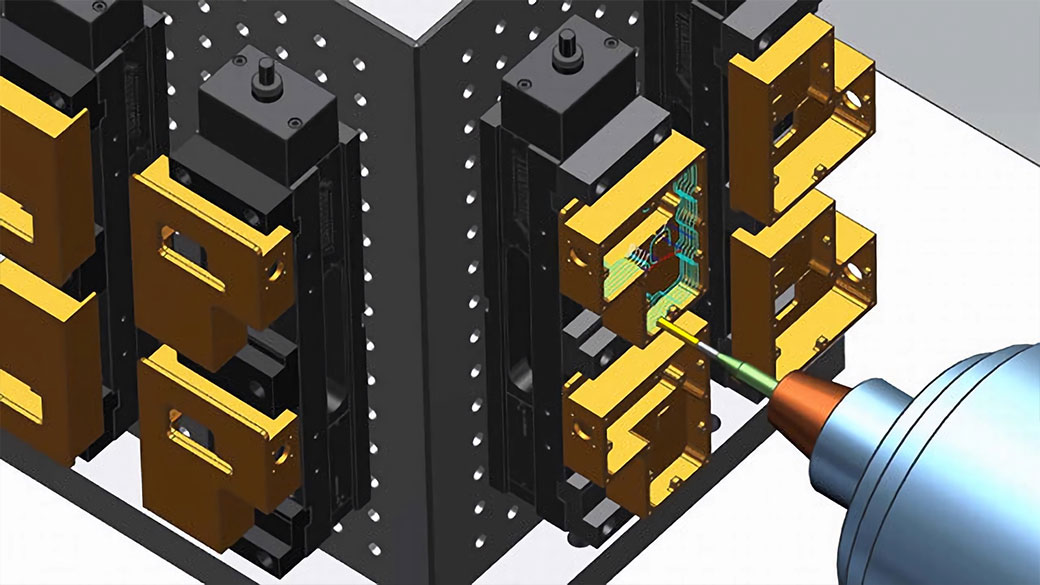

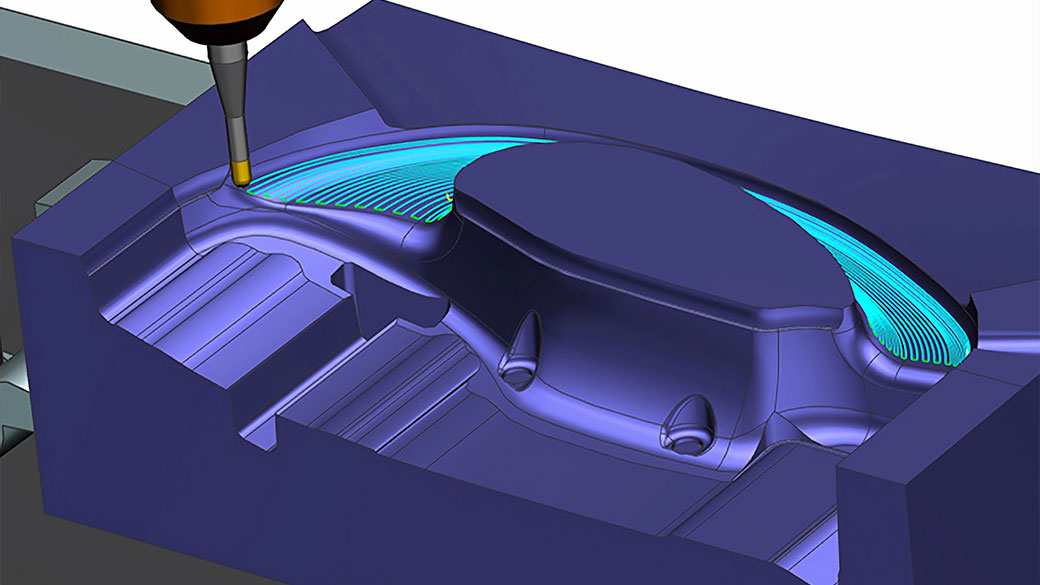

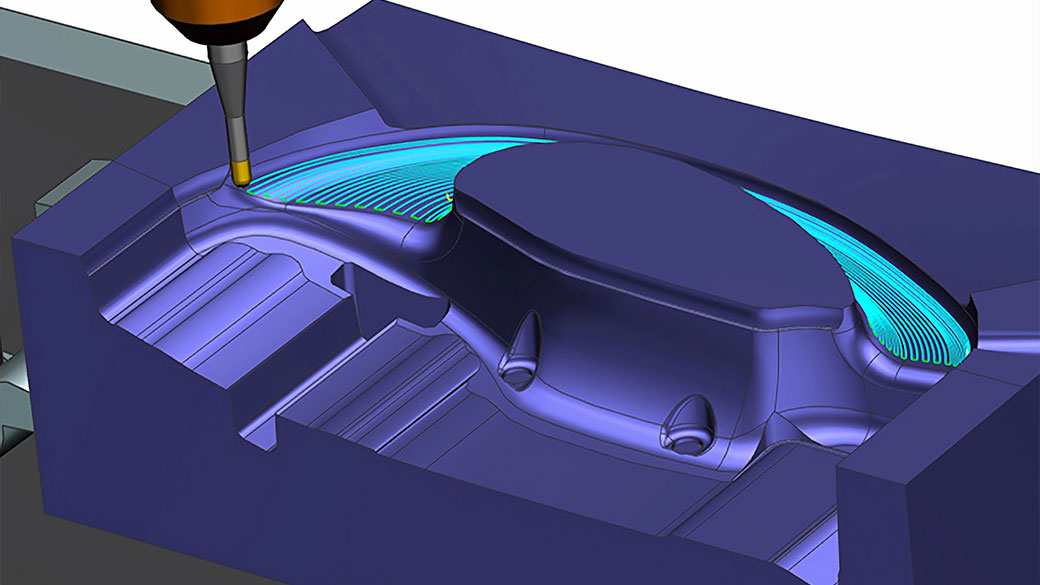

Mold, die and electrode machining

Reduce lead time using the latest 3-axis milling methods to produce molds and dies with a near-mirror finish. Powerful capabilities to manufacture high-quality tooling components include:

- High-speed cutting methods

- Automated rest milling

- Smooth finishing toolpaths

- Multi-axis machining

Design and program electrodes with an automated process using the integrated CAD and CAM capabilities in NX software.

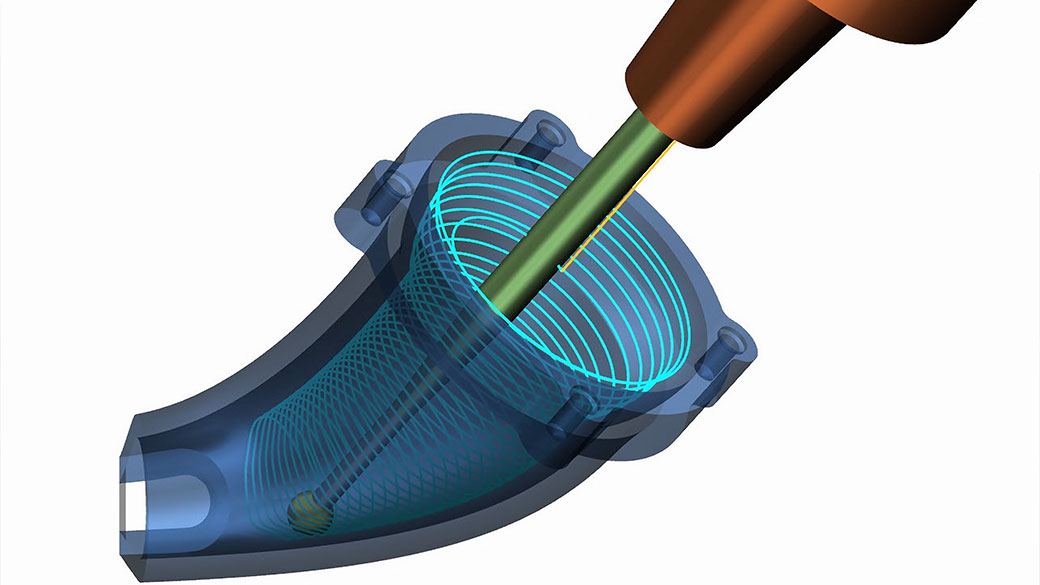

Complex parts machining

Program precisely controlled 5-axis toolpaths to effectively machine components with complex geometries and intricate details.

Using application-specific capabilities you can dramatically simplify the NC programming of challenging parts, such as impellers, blisks, and engine ports.

The integrated simulation allows you to validate the most demanding jobs—accurately improving overall productivity.

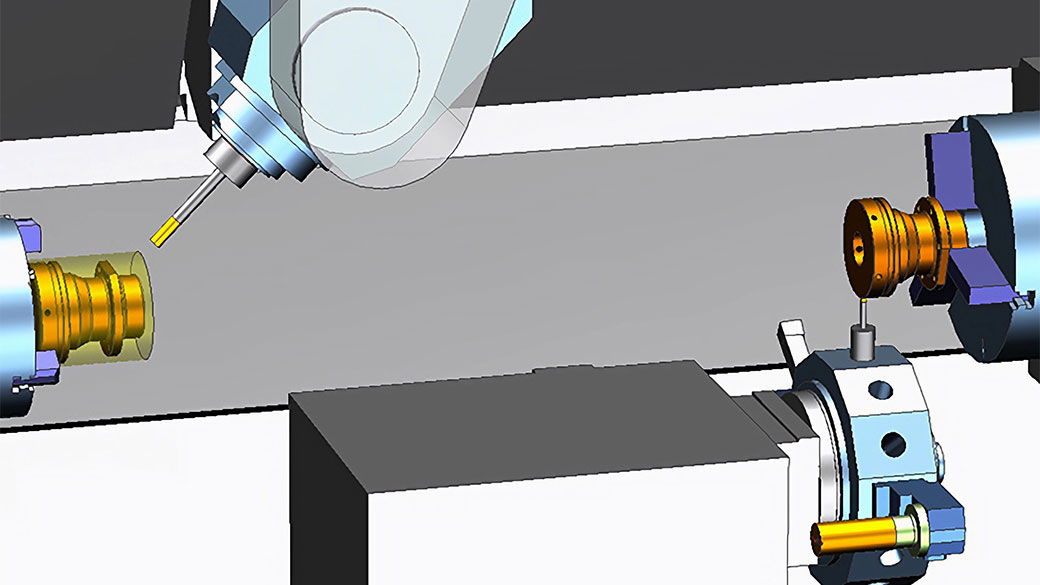

Postprocessing and machining simulation

To generate production-ready NC programs for a variety of machine tools and controls, you can use the following capabilities in NX CAM software:

Cloud-based postprocessing with over 1,000 kits that include the machine digital model, kinematics and postprocessor

Integrated machining simulation capabilities that include G-code-driven simulation that displays the motion driven from the NC code output