Tecnomatix®

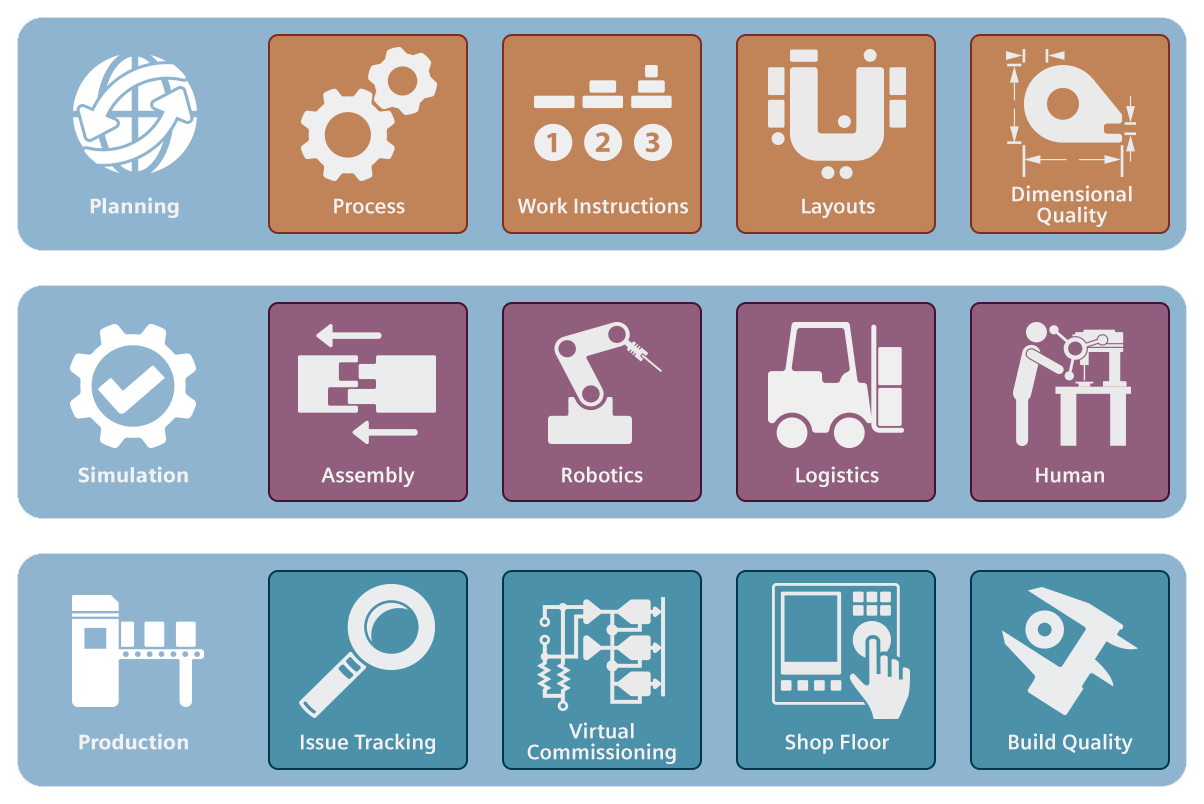

Tecnomatix® is the world’s most powerful solution for the simulation of entire facilities and virtual commissioning of production processes. Be on the right side of the growing digital divide that separates companies that verify their production flows and processes ahead of time and those that wait until mistakes happen to make costly adjustments.

The code used in Tecnomatix’s virtual commissioning can be downloaded and sent to your real-world machines to ensure seamless flow between your simulated processes and real-world processes. Perform vital production engineering work at the same time as design work to significantly reduce production times.

Why Tecnomatix®?

To become more flexible, productive and competitive in this global trend, adopting new business models with complex relationships at their foundation is possible with Tecnomatix digital manufacturing.

With Tecnomatix, the gap between product design and delivery can be bridged by handling both the manufacturing processes (design and execution) in a fully associative data model. It helps in bringing more innovative products to market faster while maintaining the critical digital continuity of the product lifecycle as well as leveraging the power of global manufacturing operations to boost efficiency, quality, and profitability.

It is one of the leading digital manufacturing solutions based on technology, industry experience, market share, and world-class customers served.

Tecnomatix solutions can be integrated with product data management (PDM) and product lifecycle management (PLM) system.

With unparalleled data management and control functions, the solution supports and improves processes specific to a range of industries, including aerospace, automotive, heavy equipment, heavy machinery, defense, high-tech electronics, and consumer products.

Tecnomatix® Process Simulate

Tecnomatix® Process Simulate is a specialized digital manufacturing solution to test PLC programs and to develop programs for robotics and manufacturing applications in 3D virtual environments. Being fully integrated with the manufacturing backbone, Process Simulate helps manufacturing engineers to validate the assembly concepts virtually even before the production starts.

Benefits of Process Simulate

Highly scalable, as it provides numerous engineering disciplines with the data and toolset to examine and verify different processes at different phases.

Reduce cost with early detection of product design issues.

Enables users to simulate multifaceted robotics manufacturing zones.

Ensure high process quality by emulating realistic processes.

Optimize cycle time.

Possess the capability to design a collision-free path for all the robots.

Provide offline programming features.

Decrease production cost by re-using tools and facilities.

Capacity to analyze the ergonomics of the human operator to ensure ergonomically safe processes.

Reduces production risks by simulating numerous manufacturing situations.

Tecnomatix® Plant Simulation

Tecnomatix® Plant Simulation software allows you to simulate and optimize production systems and processes. With Plant Simulation, the modeling and simulation of production systems and their processes get easy. Furthermore, it is possible to optimize resource utilization, material flow, and logistics for all levels of plant planning from specific lines, through local plants, to global production facilities.

Plant Simulation helps manufacturers to:

Find and eliminate bottlenecks that would otherwise require time and money for corrective measures during increased production demands

Reduce the investment cost of production lines without sacrificing the required output

Enhance the performance of existing production systems by taking appropriate measures that have been tested in a simulation environment before implementation

Key Benefits:

Boosts productivity of current facilities

Reduces inventory and throughput time

Lowers the investment in new facilities planning

Improves system dimensions, including buffer sizes

Reduces investment risks with proof of concept in the early stages

Help make the best use of manufacturing resources

Interested in speaking to our experts? Contact us now!

Tecnomatix® RobotExpert

Tecnomatix® RobotExpert software enables robotics designing, simulation, optimization, and offline programming to boost the speed, flexibility, and processing of the automated systems.

With an intuitive 3D environment, RobotExpert optimizes robotic paths with the capability to simulate virtual mock-ups of entire manufacturing cells and systems. As a manufacturer, maximize your ROI is critical. Yet the multifaceted options available in today’s robotic market means the planning, designing, and implementation of your system is highly essential to achieve the highest return.

RobotExpert supports robots from multiple vendors. It is an independent software solution, which is developed on more than two decades of experience delivering some of the most sophisticated robotic solutions applications.

It is an easy-to-deploy software supporting multiple unique industry applications, such as pick-and-place, polishing, gluing, arc welding, and many more. To meet specific manufacturing requests, it has proven track record to generate the most appropriate combination of equipment, while supporting faster product introduction, evaluation of manufacturing times, project investments, and more at the same.

Key Benefits:

Easy-to-deploy software supporting multiple unique industry applications

Virtual optimization of robotics processes

Standardized robot programming

Increased throughput due to optimized cycle time

Reduced downtime when introducing a new product or a change

Uncomplicated special robot program syntax preparation

Avoidance of costly damage to equipment during new program introduction