Deliver greater innovation and higher quality at a lower cost. With NX 3D product design software, you can interchangeably use the most productive modeling approaches—from explicit solid and surface modeling to parametric and direct modeling and facet-based modeling.

Reach out to our team of experts to discuss your unique needs and goals. We’re excited to show you how NX from Siemens Digital Industries Software will revolutionize your design & engineering workflows.

The Problem

Companies around the world are struggling to keep up with the demand for more innovative, integrated products with shorter time-to-market. The rise of additive manufacturing has changed the way teams look at product geometries and performance, and the growing need to make all products “smart” has made even the simplest products more complex and integrated. In this rapidly changing environment, legacy 3D modelling software just won’t cut it.

That’s where NX CAD from Siemens Digital Industries Software comes in.

The Solution

Learn about all the ways NX CAD can help your company create better, smarter products faster.

Adaptive User Interface

Leverage the NX personal assistant that uses artificial intelligence (AI) and machine learning to track and learn from user actions. This feature predicts the NX commands you will likely use next based on the context of what you are currently doing. It then presents those commands on a compact adaptive user interface (UI) panel. For example, if you’re doing something in sheet metal, it knows that a certain sequence of commands will be used and it will provide them to you.

Convergent Modelling

Perform faceted-based modeling without needing data conversion. By combining facet, surface and solid modeling in a single integrated environment, NX eliminates the need for reverse engineering. Simply model with topology optimization results directly. Convergent Modeling, compared with traditional modeling techniques, can be up to ten times faster.

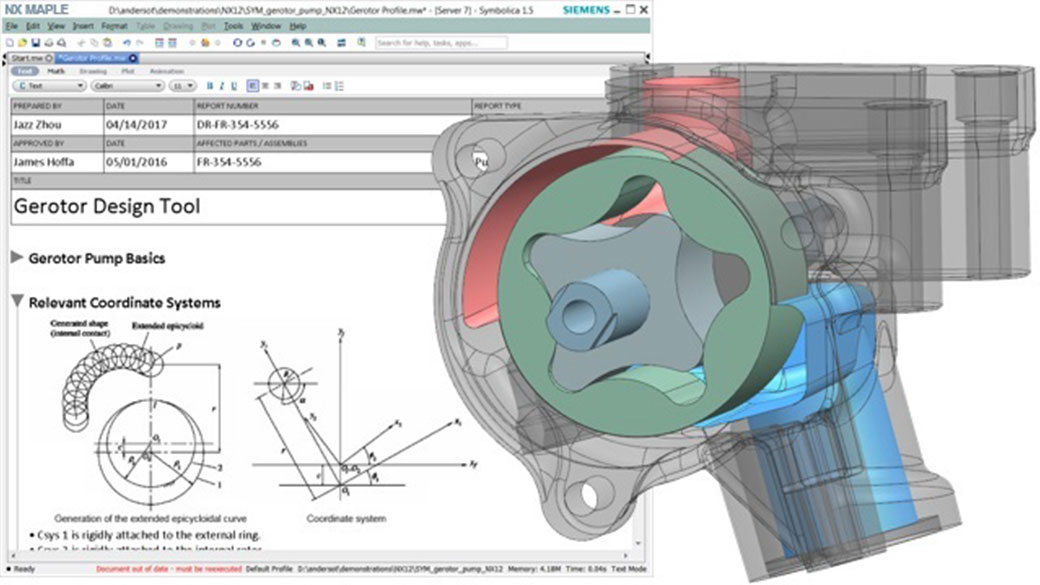

Equation-driven modelling

Certain functional surfaces and solids are most easily defined using mathematical equations. Functional examples include optical surfaces, cam profiles, airfoil geometry and any other geometry for which you can define the math. Using Convergent Modeling, equation-driven geometry can be specified using robust 3D plotting tools in NX Maple and then associatively incorporated into NX designs for further refinement.

NX Maple can easily handle algebraic math, differential and integral calculus, differential equations, linear algebra and much more. You’ll have complete control over the smoothness or resolution of equation-driven geometry created by NX Maple. Also, the intellectual property defined by NX Maple worksheets can easily remain managed within Teamcenter.

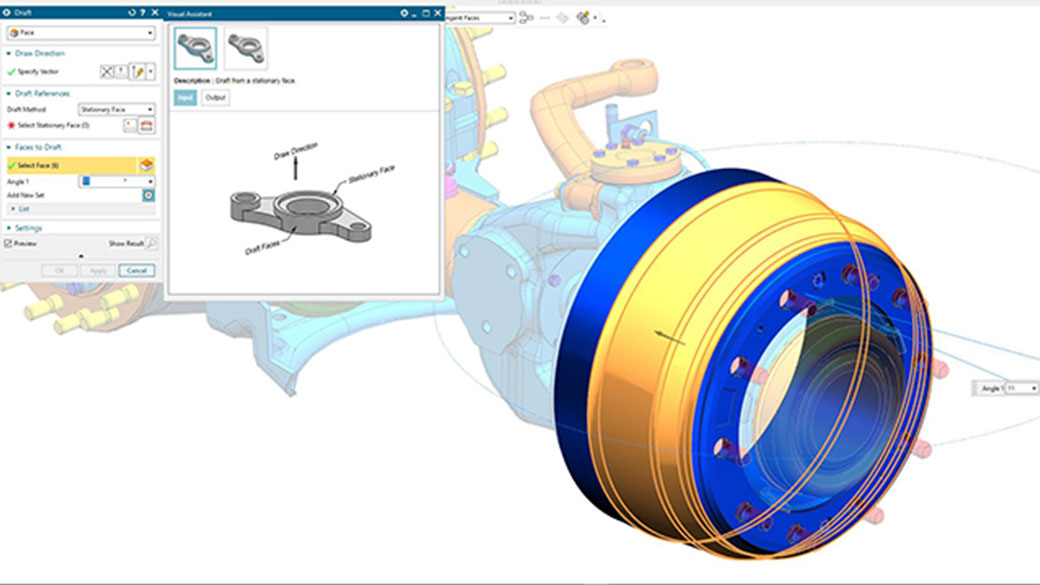

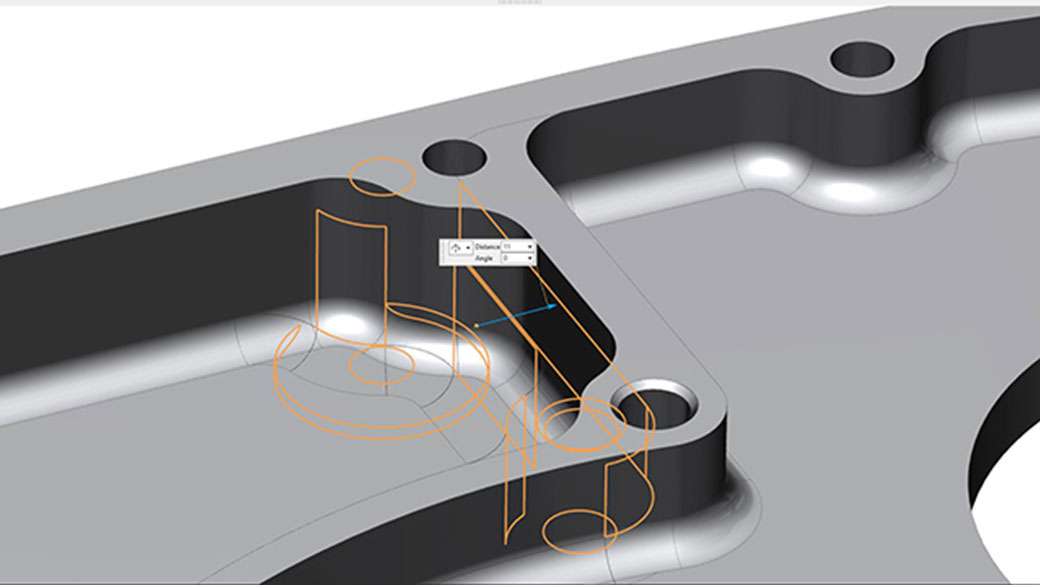

Synchronous Technology

Experience synchronous technology, a collection of simple, direct pull/push tools for editing and creating both 2D and 3D geometry.

Perform fast and intuitive modeling with NX—freely modify 3D geometry without needing to understand how models were constructed using simple push-and-pull methods. You can use synchronous modeling interchangeably with all other CAD modeling tools—on NX models or geometry from any other source for greater versatility.

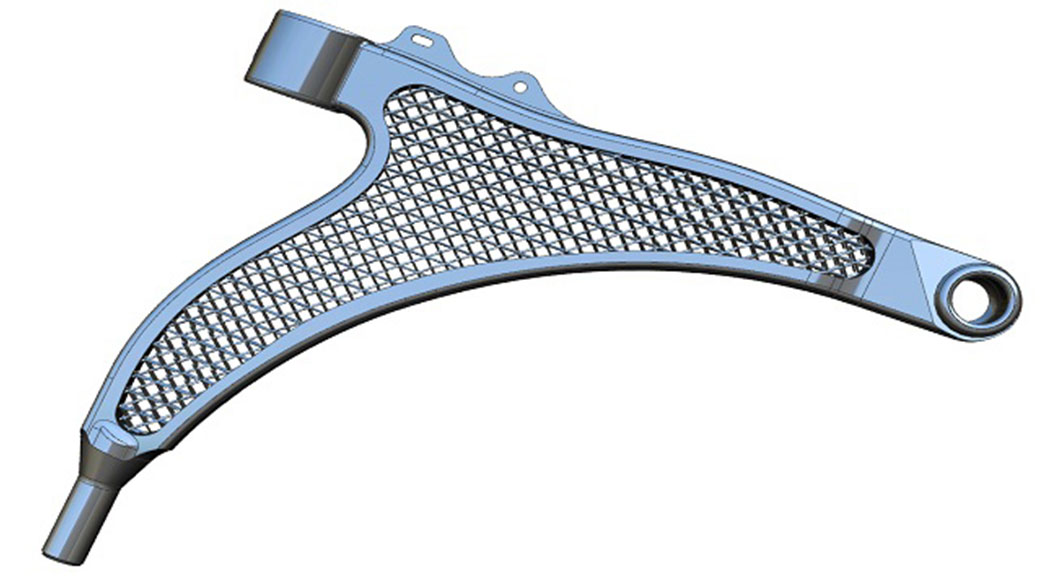

Topology Optimization and generative engineering

Create and optimize a new generation of products by taking performance requirements into account from the start. Compressed schedules often force engineers to choose the first feasible design option. By mimicking nature’s evolutionary approach, generative engineering empowers you to identify the best design sooner, while reducing the number of iterations needed.

Automated calculations iterate until optimized geometry is achieved. The resulting organic shapes are lightweight and meet all performance requirements. NX allows you to automate the design exploration process.

2D and 3D CAD Modelling

Use any modeling approach that fits your design challenge—with the versatile NX CAD modeling tools—and get innovative products to market faster.

- Assembly design

- Feature modeling

- Freeform design

- NX Sketch

- Sheet metal design

- Template-based design

Design for Additive Manufacturing

Meet the unique challenges of designing, optimizing and building metal and plastic components using the latest additive manufacturing methods. Our breakthrough technology delivers advanced methods for designing lightweight parts, while design validation checkers ensure manufacturability.

- Design rules

- Lattice structures

- Manufacturing preparation

Training Options

Want to get the most out of your digital industry solution? Explore our training options below to give your team the skills & knowledge they need to succeed.

Consulting Options

Need help implementing or managing your NX CAD, Simcenter, or CAM solutions according to industry best practices? Our team will work with you to make sure your solutions are implemented and used in the optimal way.

Connect with us today to learn more.

Resources

Please consult our LTS Insights page for more information on best-in-class solutions and practices for digital industry.