Electrode Burning Code

Automation Solution

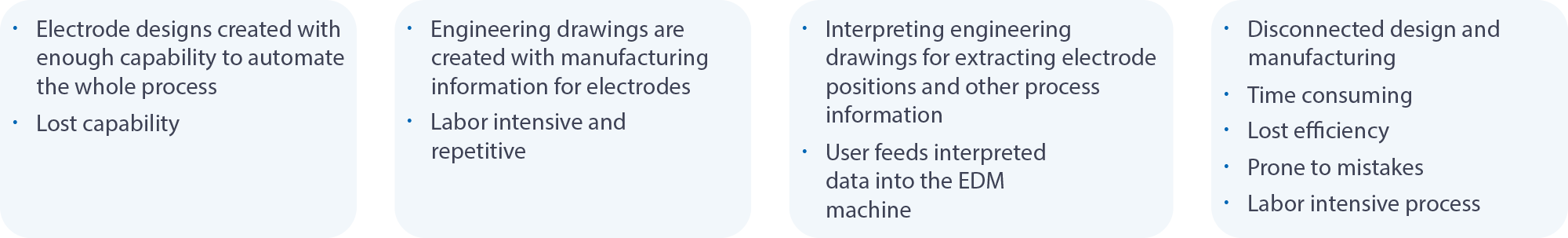

This state-of-the-art application provides a user-friendly interface where you can automatically generate electrode burning codes from electrode designs. Reduce errors by eliminating the need for drawings and manual user input to EDMs. Verify electrode designs with tool position mapping and motion simulation.

Autoburn for NX (PDF) >

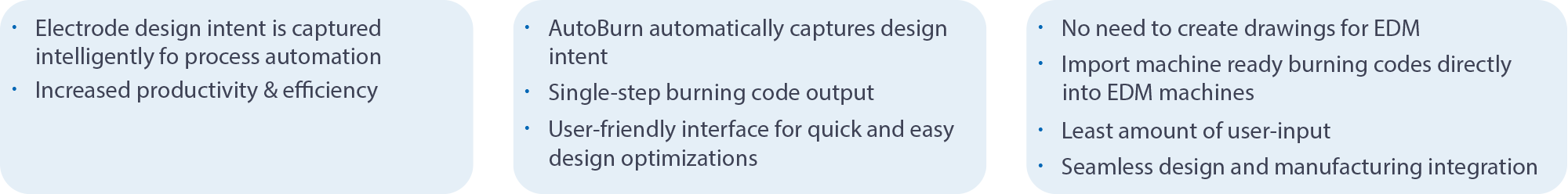

Do you struggle with any of these challenges?

– Do you need to streamline your Electrical Discharge Machining (EDM) process?

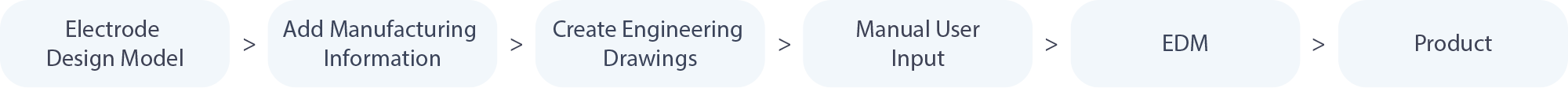

– Are you spending unnecessary time and effort adding additional information to an already rich design?

– Is there a disconnect between your design and manufacturing environments?

– Do you have to create cumbersome engineering drawings from your electrode design models?

– Does your EDM team struggle to interpret engineering drawings to input burning codes into your EDM machine?

– Are your processes labor intensive and prone to mistakes?

If yes, then we have a unique solution to address your challenges:

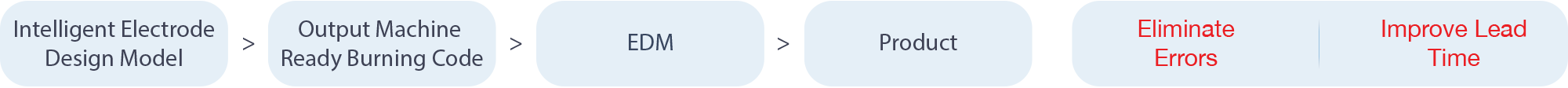

– Streamlines the overall EDM process

– Saves time and effort

– Reduces setup times

– Creates a seamless link between your design and manufacturing work

– Eliminates the need to create drawings for EDM

– Virtually verifies electrode motion before actual manufacturing

– Generates machine ready-burning codes for EDM machine

– Reduces costly errors through process automation

Business Benefits

Increases Profits

High ROI

Eliminates Errors

Improves Quality

Improves Lead Time

Provides Competitive Edge

Quick Implementation

Requires Limited Training

User Benefits

No need to create and interpret drawings to input parameters into the EDM machine.

Automatically generate accurate and machine-ready burning codes from design model.

Easily specify electrode burning direction and modify burning parameters.

Verify design intent by virtually simulating design and output setup sheets.

Work inside of Siemens NXTM in a user-friendly interface requiring limited training and setup.

Scalable support for most popular EDM machines in the industry.

Workflow Comparison

Typical

AutoBurn