We’re the most trusted and experienced partner for NX Die Design and NX Progressive Die Wizard in North America.

Reach out to our team of experts to discuss your goals. We’re excited to learn more about your unique needs and to show how NX for Die Design will revolutionize your design and engineering workflows for stamping dies.

The Problem

Die shops around the world often struggle to match customer requirements with streamlined workflows, especially when it comes to tool design. These same companies often design their stamping dies with solutions that require too much manual design work, leading to inefficiencies that make shops less competitive.

That’s where NX for Die Design from Siemens Digital Industries Software comes in.

The Solution

Imagine a solution that can lead your users through the stamping die design process from start to finish, automating the unfolding of parts and re-use of common components while absorbing the wisdom that currently exists only in the heads of your most experienced designers. Now imagine pairing that software with a team of support engineers from Longterm Tech who have decades of experience in the tooling business.

Learn more about the many ways NX for Die Design and the team of experts at Longterm Tech will take your company to the next level.

Create sheet metal part designs

Imagine being able to optimize the design of both straight break and freeform sheet metal parts with a broad set of sheet metal functions. NX Die Wizard helps you leverage feature recognition, bend table, and direct unfolding capabilities to design associative intermediate stage parts with prebends and overbends.

Apply One-step Unforming and Formability Analysis technology to create intermediate forms and flattened blank shapes for complex freeform parts.

Define complete processes

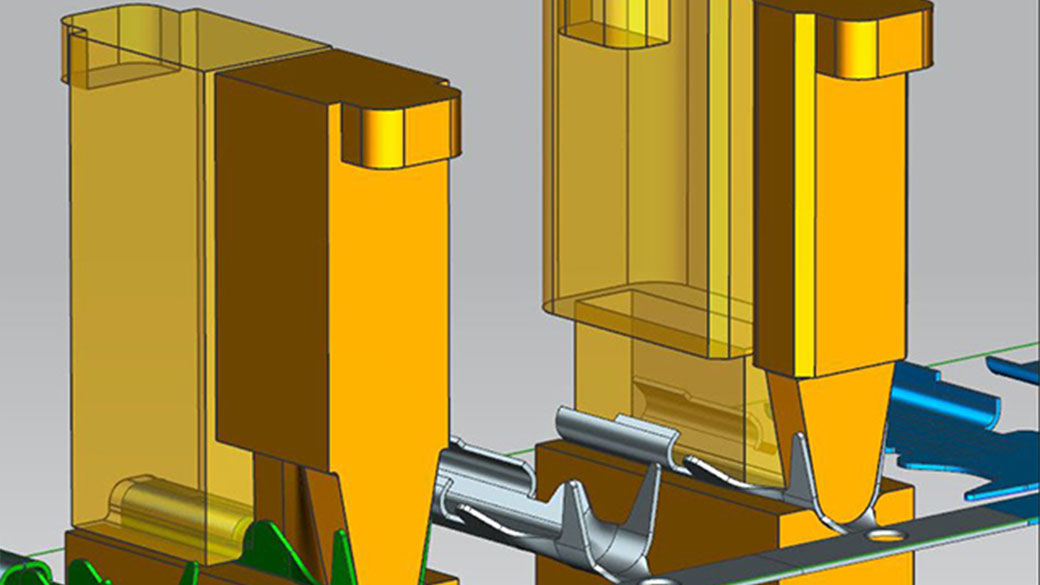

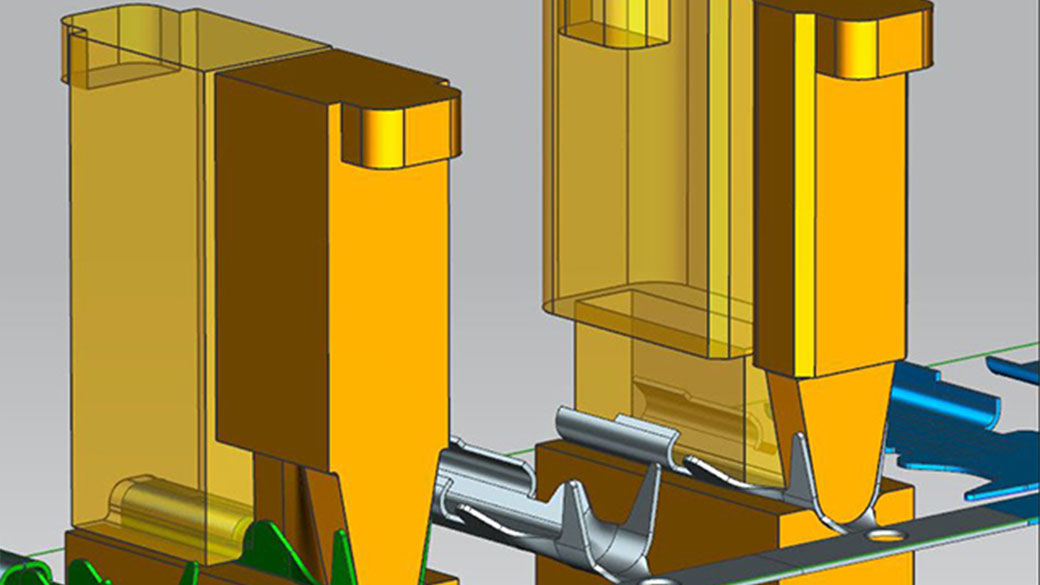

Use an optimized workflow to specify details of the strip layout and the progression of each design stage, while simulating the manufacturing of the strip.

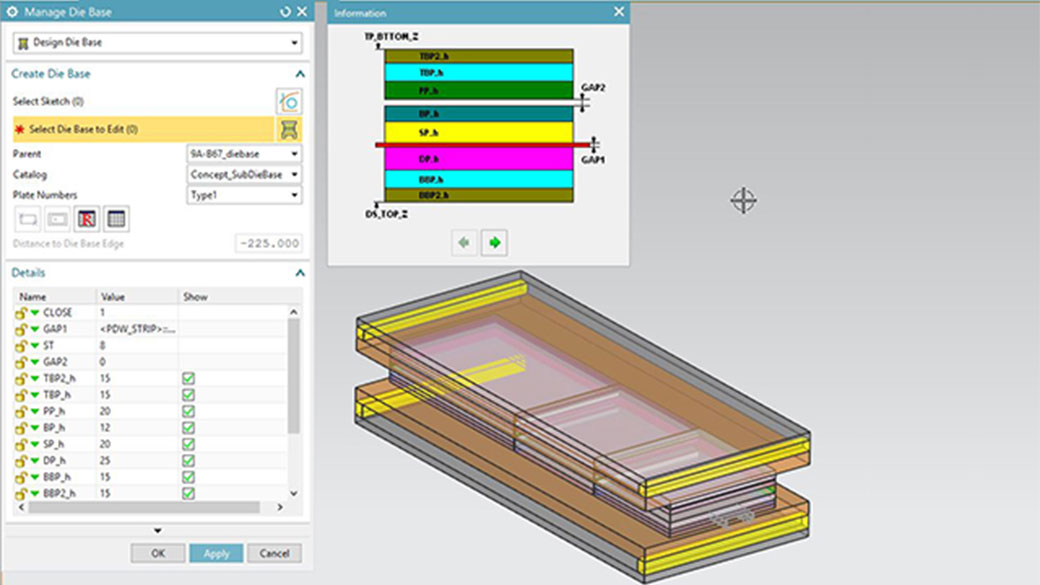

Design die base assembly and die inserts for forming and punching operations. Access a library of standard parts, including catalogs of major suppliers. The customizable base die libraries, standard parts and insert groups streamline the design of die structure.

Reuse company standards

Reuse knowledge of designs and operations to streamline processes, from tooling design to production. Leverage project templates, materials, tools and processes to reuse and adapt proven designs to new dies.

Build reusable parts, register them in custom libraries and develop reusable die configurations. Generate parts lists, drawings, project data structures and NC toolpaths.

Update die designs using associativity

Quickly incorporate design updates using the associativity with the part model throughout the die development process.

Work concurrently with your team members, searching, accessing and reusing project data and processes with the management of data and processes.

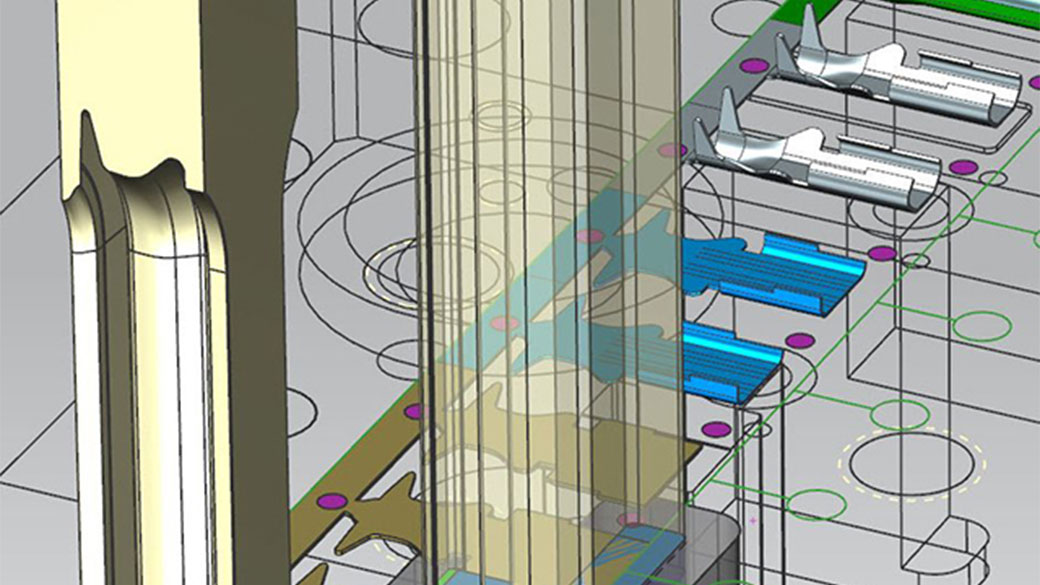

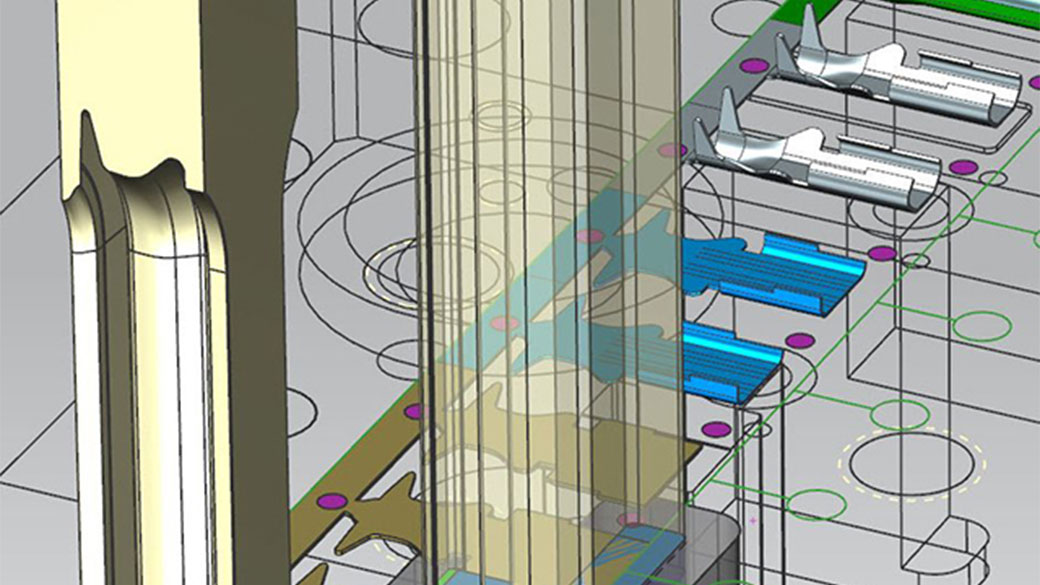

Validate progressive die designs

Validate the design of the progressive die within the assembly context for proper clearances and reliefs in various positions stated. You can analyze material usage of the strip layout and press force balance, and simulate the strip progression.

Motion simulation with dynamic collision detection helps you verify correct operation in the entire range of die movements.

Eliminate collisions, optimize strokes-per-minute and transfer curves

Our team of dedicated experts has developed Dynmik Design for Die (DDD), a unique solution that performs full motion simulation and collision-checking on your tools with minimum setup or training required. Designed specifically for the stamping die industry, DDD allows you to:

- Optimize Press Parameters

- Detect and eliminate tool/transfer collisions

- Dynamically present verified design to customers with compelling animation

Learn more at our Dynmik Design product page

Training Options

Want to get the most out of your digital industry solution? Explore our training options below to give your team the skills & knowledge they need to succeed.

Consulting Options

Need help implementing or managing your NX CAD, Simcenter, or CAM solutions according to industry best practices? Need help validating your mold and die designs using motion simulation? Our team will work with you to make sure your solutions are implemented and used in the optimal way.

Connect with us today to learn more.

Resources

Please consult our LTS Insights page for more information on best-in-class solutions and practices for digital industry.