We’re the most trusted and experienced partner for NX Mold Design and NX Mold Wizard in North America.

Check out our case study with Cavalier Tool & Manufacturing below to learn more, or reach out to our team to discuss your unique needs and goals. We’re excited to show you how NX Mold Design will revolutionize your tooling design and manufacturing workflows.

The Problem

Mold shops around the world often struggle to match customer requirements with streamlined workflows, especially when it comes to mold design. These same companies often design their tools with solutions that require too much manual design work, leading to inefficiencies that make shops less competitive.

That’s where NX Mold Design comes in.

The Solution

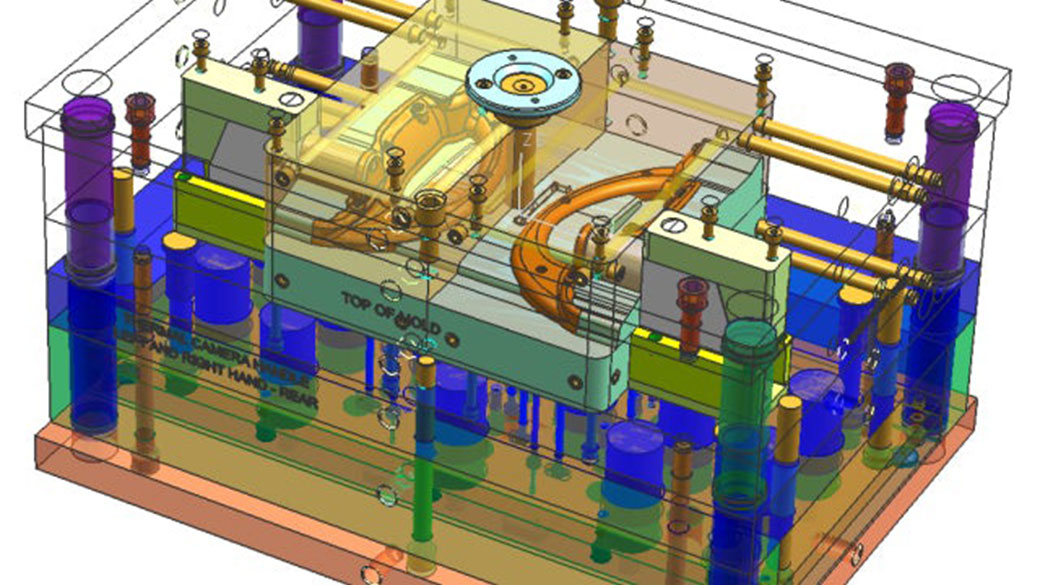

Imagine a solution that can lead your users through the mold design process from start to finish, automating the creation of mold bases, standard parts, cooling channels, and common components while absorbing the wisdom that currently exists only in the heads of your most experienced designers. Now imagine pairing that software with a team of support engineers who have decades of experience in the tooling business.

Learn more about the many ways that NX for Mold Design and the experts at Longterm Tech will take your company to the next level.

Product analysis

Start the mold design by designing the product. You can open any standard CAD files or select parts designed with NX. Ensure desired design intent and manufacturability by modeling, making design changes and analyzing geometry.

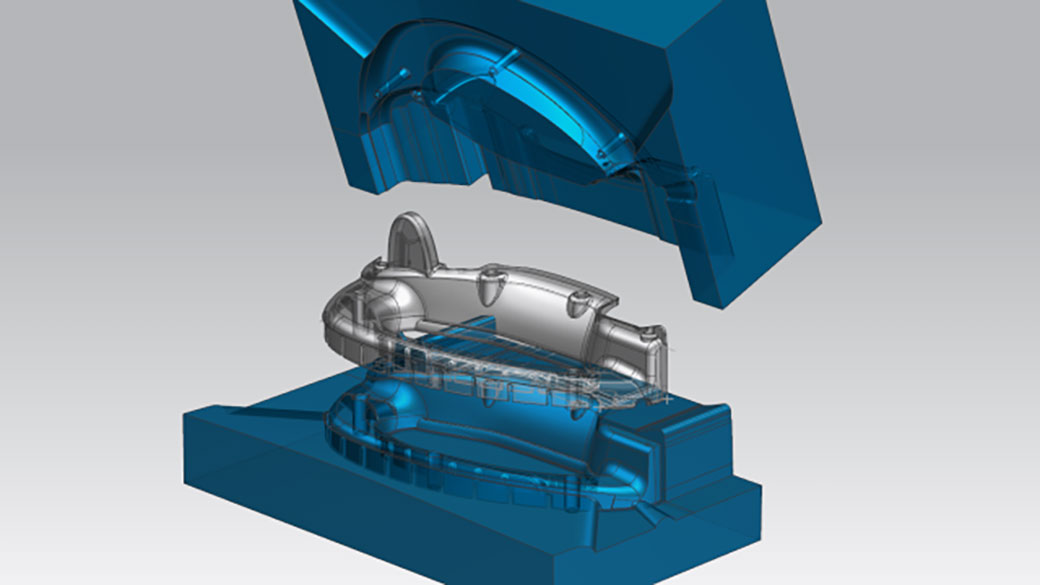

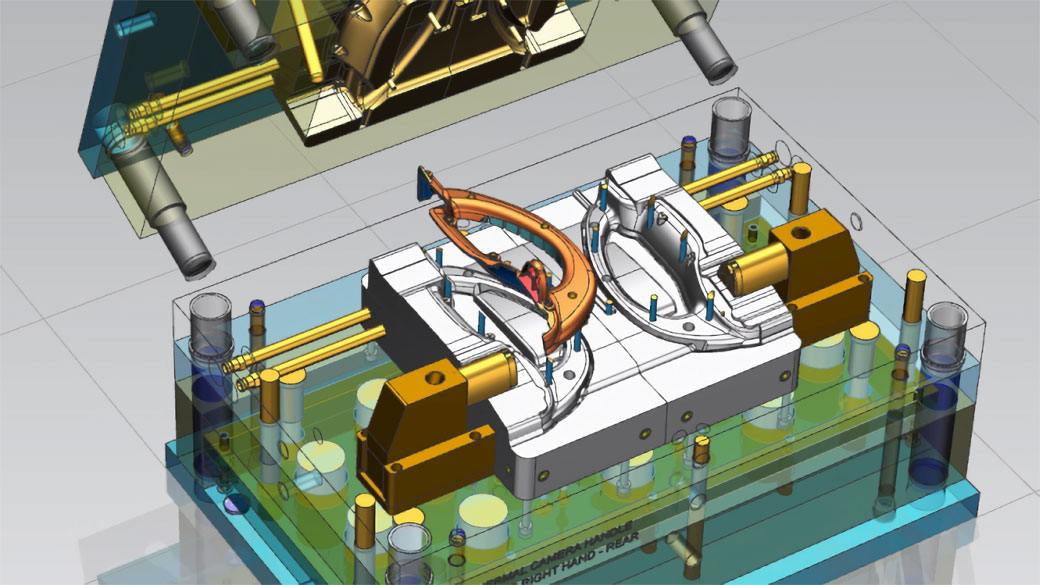

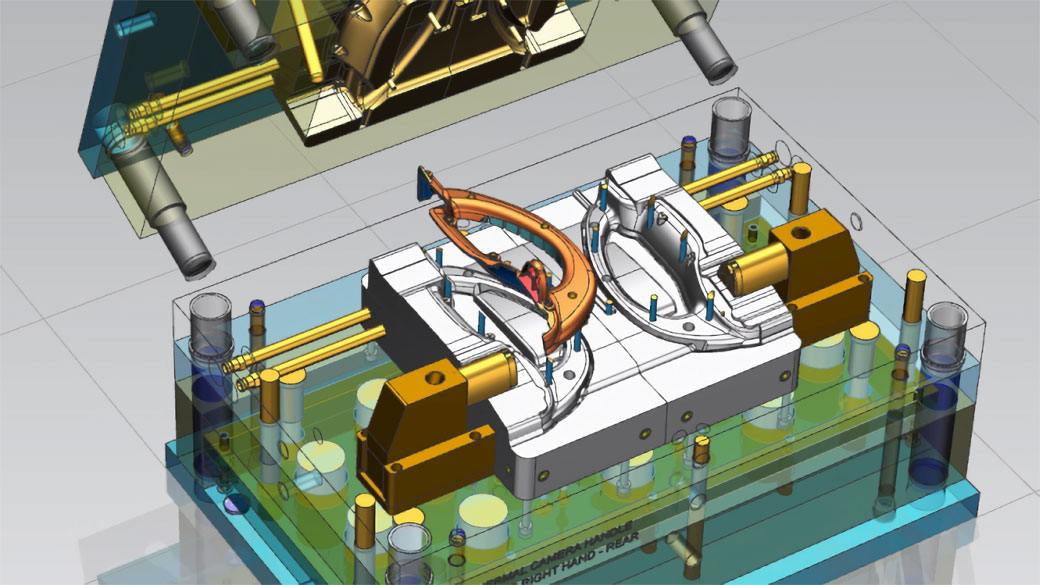

Core and cavity development

Imagine streamlining your design process for core and cavity geometry using automated capabilities, enabling you team to:

- Use automated shutoffs and a parting of core/cavity

- Design parting surfaces quickly and associatively

- Split mold to accommodate complex slider designs

- Automatically check the core/cavity design for interferences

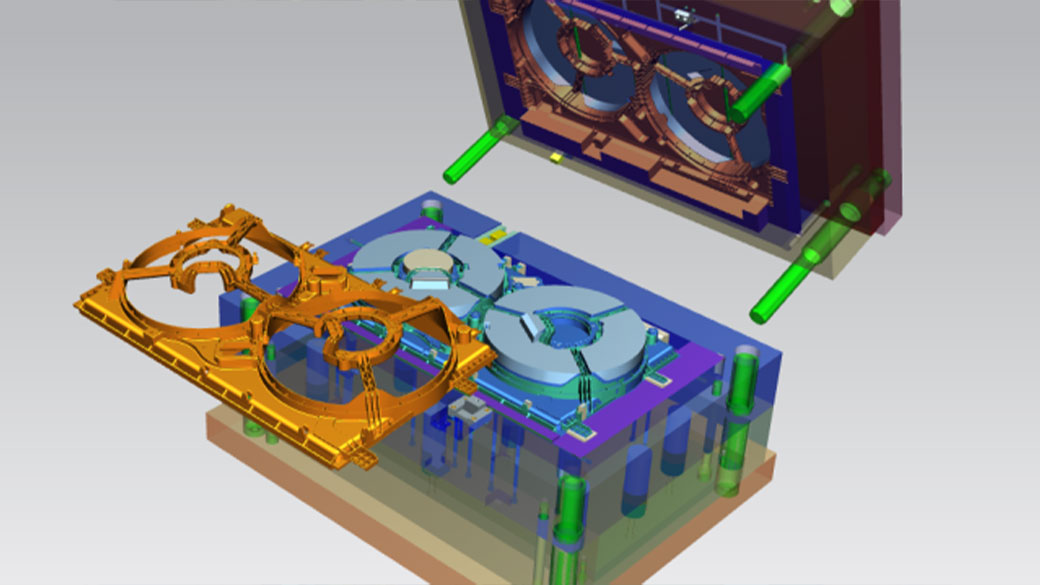

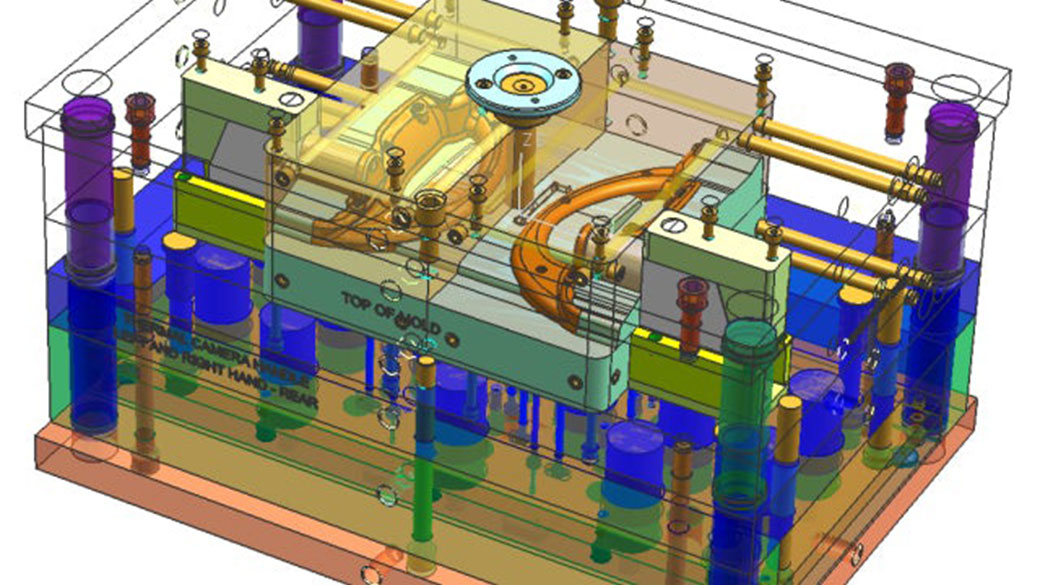

Mold structure

Easily define the entire mold structure, including the core, cavity, component systems, and mold base for both prototype and production-scale multi-cavity molds.

Configure the mold using libraries of standard parts, component systems and mold bases. Quickly add and trim ejector pins and insert cooling channels with parametric patterns. Include runners, gates, screws, pins, and other standard components.

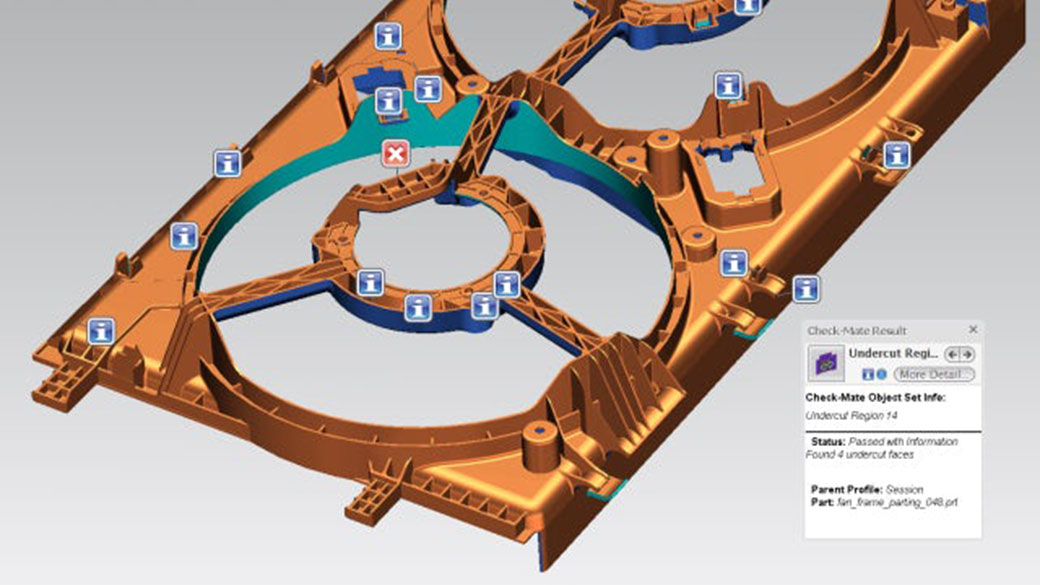

Design validation

Analyze the manufacturability of part designs using tools to check wall thickness, identify undercut regions and evaluate corner radii.

Validate the mold design by checking the distances and reliefs in various positions and by analyzing the requirements for electrodes.

Use the motion simulation capabilities to verify the entire range of movements of the mold, including dynamic collision detection.

Reuse of company standards

Reduce tool development time by reusing your company’s standards, including:

- Repurpose project templates and adapt proven designs to new molds

- Accelerate the mold design process by standardizing components

- Automate generation of NC toolpaths and project data structures

- Develop reusable mold base configurations and save them in custom libraries

Design change and propagation control

Use the associativity with the part model to facilitate rapid propagation of design changes through the process, from mold design to machining operations.

Ensure that the entire team works with the correct data by integrating the Teamcenter software, which provides a single source of data and process knowledge.

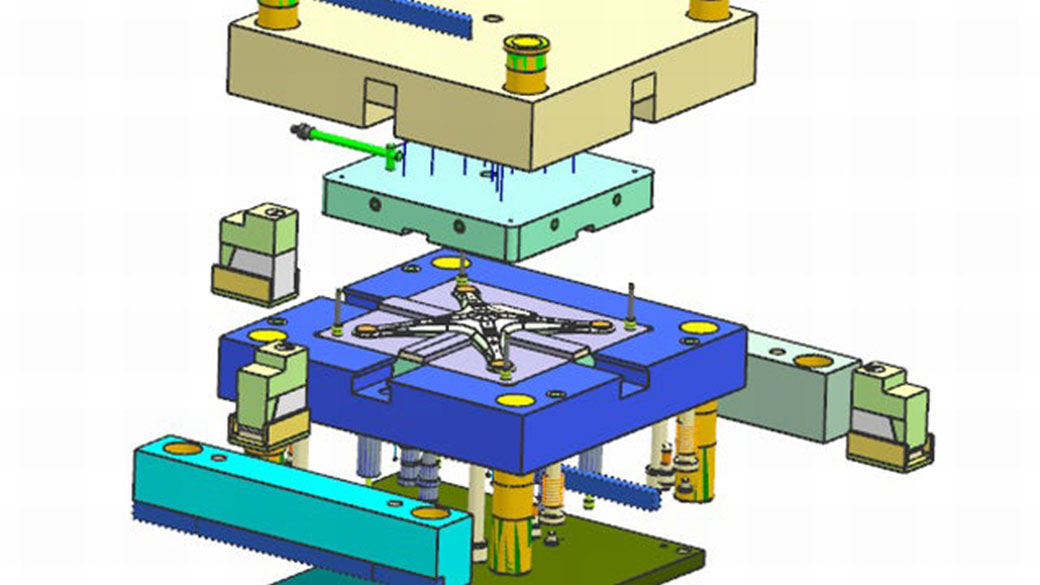

Eliminate collisions and validate designs using 4D simulation

Our team of dedicated experts has developed Dynmik Design for Mold (DDM), a unique solution that performs full motion simulation and collision-checking on your tools with minimum setup or training required. Designed specifically for the mold industry, DDM allows you to:

- Verify complex mechanisms

- Check designs for potential interference conditions to avoid costly damage caused by collisions

- Reduce design review time with customers

- Dynamically present verified design to customers with compelling animation

Learn more at our Dynmik Design product page

Training Options

Want to get the most out of your digital industry solution? Explore our training options below to give your team the skills & knowledge they need to succeed.

Consulting Options

Need help implementing or managing your NX CAD, Simcenter, or CAM solutions according to industry best practices? Need help validating your mold and die designs using motion simulation? Our team will work with you to make sure your solutions are implemented and used in the optimal way.

Connect with us today to learn more.

Resources

Please consult our LTS Insights page for more information on best-in-class solutions and practices for digital industry.