Machine builders need to become more agile and reliable in how they design and build their product. Teams working in silos must be brought together on a collaborative platform to pursue bolder designs, better cycle times, and higher-quality machines.

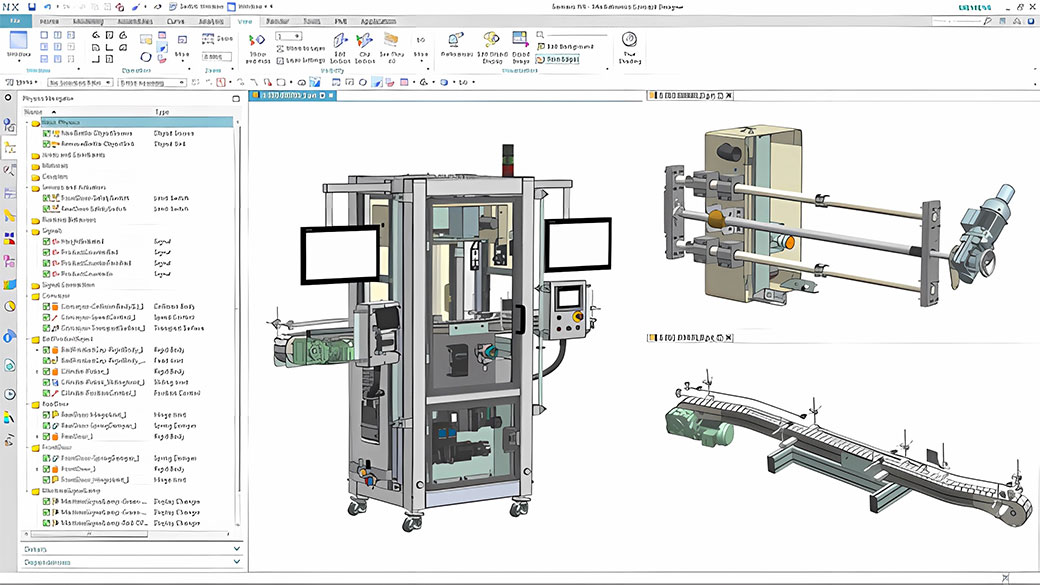

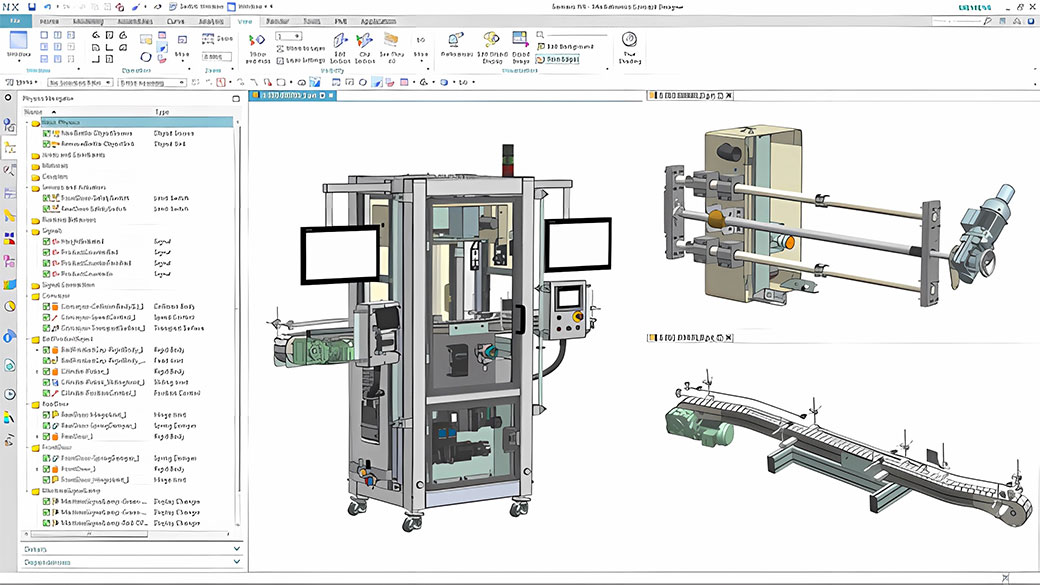

Check out our webinar on the right to learn how NX Mechatronic Concept Design can help you eliminate machine errors during commissioning and pursue bolder designs on faster timelines. Or Reach out to our team of experts to discuss your unique needs and goals. We’re excited to show you how NX Mechatronic Concept Design from Siemens Digital Industries Software will revolutionize your design and validation workflows.

The Problem

Many companies feel lots of stress when they commission a new machine for the first time. Issues with mechanical collisions, software bugs, or electrical faults are almost a given for most companies that reach this stage. These companies simply accept these risks and inefficiencies and tinker with physical prototypes until they have the machine they want. But this approach leaves them vulnerable to unacceptable lead times, added expenses, and declining competitiveness compared to companies that are digitalizing their machine design and prototyping processes.

The Solution

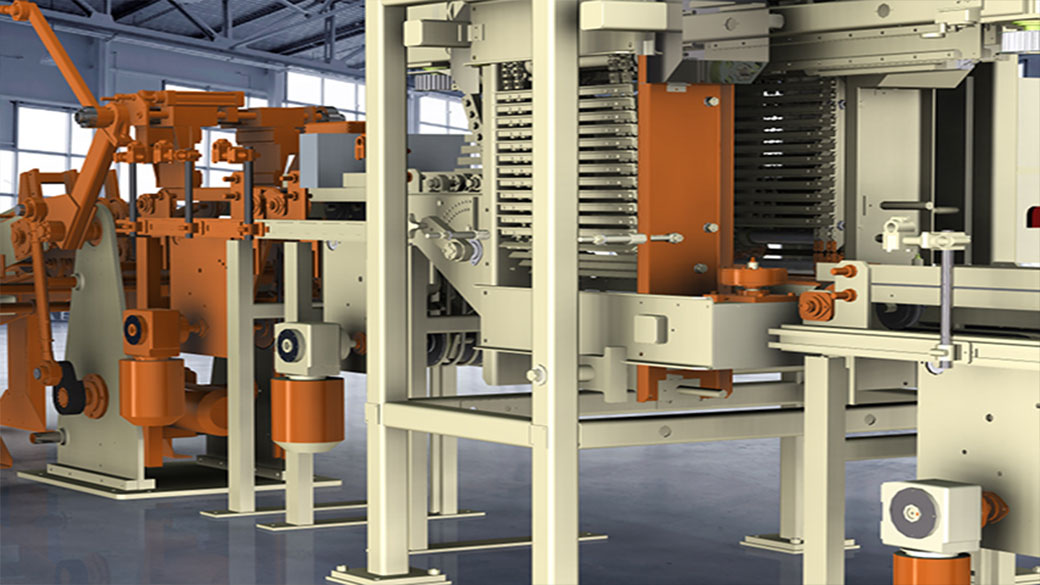

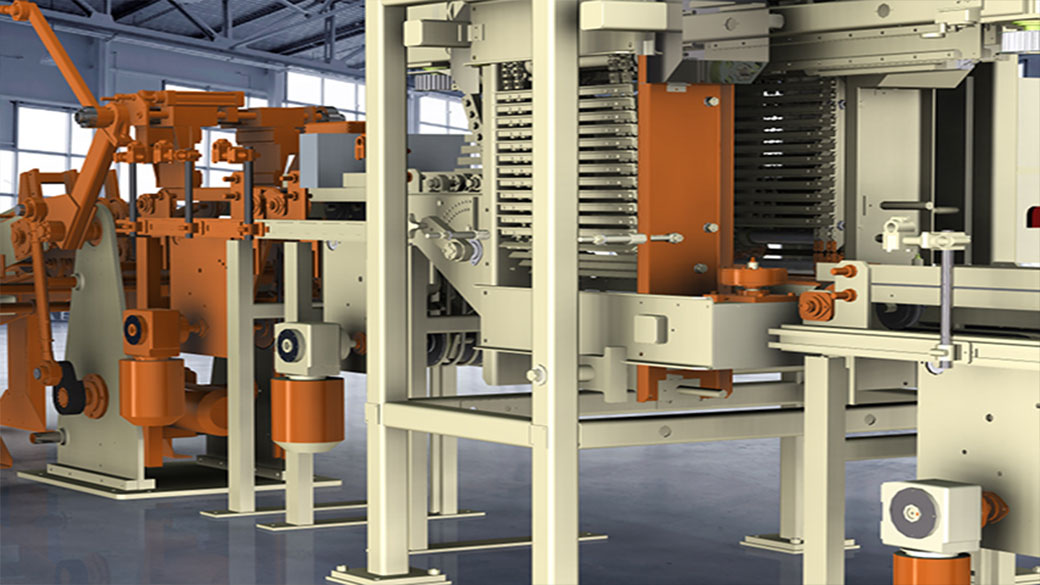

Imagine a single software that lets your mechanical, electrical, and automation engineers take a multidisciplinary approach to machine design. Bring your existing CAD/ECAD data and controls software seamlessly into a platform that creates a true digital prototype of your machine. That means bolder designs, shorter lead times, and fewer errors at the commissioning stage to save you time and money.

Just look at how Tronrud Engineering accomplished this goal using NX Mechatronic Concept Design.

Integrated system engineering approach

NX MCD allows you to trace customer requirements through to a finished design using systems engineering principles. A functional model provides a common language for mechanical, electrical and automation disciplines to work together in parallel, which helps you deliver designs faster and with fewer integration issues late in your design process.

Open interfaces to other tools

Use the output of Mechatronics Concept Designer to continue to refine designs without the need to remaster the data—this can be done directly by multiple disciplines.

- Mechanical designers can use concept models in NX for detailed design

- Electrical designers can use model data to select sensors and actuators

- Automation designers can use cams and operation sequence information from the model for software development

Physics-based simulation capability

Quickly create and validate alternative design concepts early in the development cycle, leveraging easy-to-use modeling and simulation in Mechatronics Concept Designer (MCD). Unlike a model-based tool, MCD enables you to see what the design looks like and validate that it works.

While model-centric tools show you the geometry and allow you to model the parts, we go further and enable you to validate that your product works before you build it. The Reuse Library enables this validation, from which you can quickly add data to the functional model. This data includes joints, motion, sensors, actuators, collision behavior and other kinematic and dynamic properties for each component. This allows a physics-based, interactive simulation to verify machine operation, which in turn detects and corrects digital model errors.

Training Options

Want to get the most out of your digital industry solution? Explore our training options below to give your team the skills & knowledge they need to succeed.

Consulting Options

Need help implementing or managing your NX CAD solutions according to industry best practices? Our team will work with you to make sure your solutions are implemented and used in the optimal way.

Connect with us today to learn more.

Resources

Please consult our LTS Insights page for more information on best-in-class solutions and practices for digital industry.