Introduction

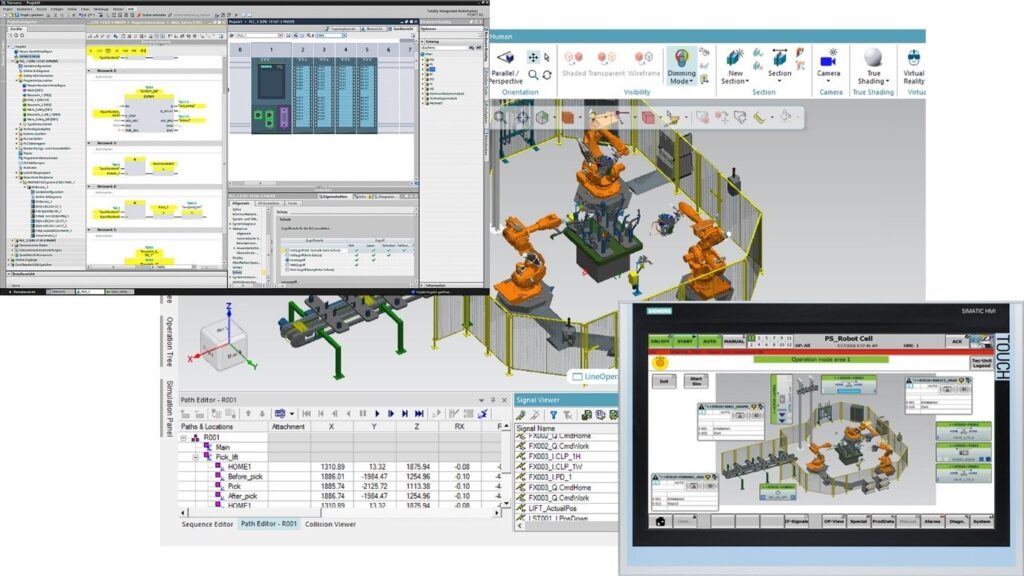

Virtual Commissioning (VC) is revolutionizing industries by allowing businesses to thoroughly test and optimize production processes before physical implementation. Siemens leads this transformation with its advanced VC technology, delivering faster, safer, and higher quality commissioning. This article explores the unique advantages of Siemens VC and highlights successful case studies with Estun Automation and Wipro PARI, demonstrating its real-world impact.

Siemens Virtual Commissioning

Source: Siemens Digital Industries Software

How Siemens VC Stands Out

Superior Capabilities

Shortening Commissioning Time Digital Twin Integration Collaboration Enhancement Cost-Effective Concept Validation Reduced Dependency on Physical Tryouts Virtual commissioning creates a shift in implementation behavior Estun Automation overcame long design cycles and high hardware costs by implementing Siemens’ virtual commissioning technology. This streamlined their design and validation process for a battery and photovoltaic production line, cutting project costs by 20% and commissioning time by 30%. The use of virtual commissioning also improved collaboration and enhanced their digital twin capabilities. Wipro PARI drastically reduced commissioning time by 70% for an engine assembly line using Siemens’ virtual commissioning tools. This led to a 40-50% decrease in rework and improved process reliability early on. The company plans to expand its virtual commissioning capabilities due to the success of this implementation.

Source: Siemens Digital Industries Software Case Studies

Estun Automation

Wipro PARI

To Summarize