Is your shop still using ERP or Excel to set your production schedule?

If so, you’ve probably dealt with the frustration of seeing your on-time delivery rate blown up by a sudden material shortage, unplanned machine maintenance, or any of the other unforeseen problems faced by toolmakers every day.

If only there were a way to automatically generate your best possible production schedule, even if something went wrong.

Well, there is, and it’s being used by companies all over the world.

High-mix, low-volume challenges

Production scheduling can be especially tough in high-mix, low-volume environments. Companies need to be lean, agile, and smart all at the same time. And until now, the received wisdom has been to find someone who’s really good at manually manipulating Excel sheets. Or maybe you’d use an ERP system to create buckets of capacity and hope they were enough to fill your production needs.

But all along, you’ve known there must be a better way. A way to schedule production without waste, and with the flexibility to instantly address any new constraints without impacting your OTD.

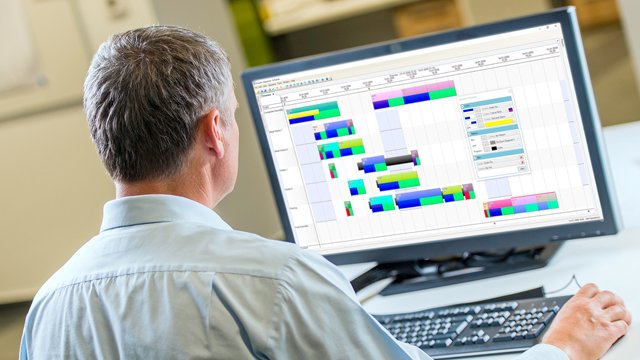

If any of this rings true, we suggest you consider putting advanced planning and scheduling (APS) on your roadmap for improving your shop’s production efficiency. An APS is a solution that takes your order and shop floor data and automatically generates the best possible production schedule in as little as one click. The solution then produces a schedule for all of your resources down to the minute, factoring in all of your real-world constraints and business rules.

Production scheduling might not seem like the next exciting frontier of efficiency improvements. But over the past few years, we’ve seen companies use APS to:

- -Increase top-line revenues by 10%

- -Decrease inventory by 50%

- -Increase schedule adherence by 35%

- -Decrease the time taken for production scheduling from two weeks to ten minutes

These numbers might seem incredible, but they’re drawn from real-world companies. If you’d like to learn more about how these improvements are possible in the tooling industry, please don’t hesitate to reach out to us. We’d love to show you how you can achieve these kinds of improvements with very little up-front investment or risk.