Building on our last blog, where we introduced Siemens Tecnomatix Plant Simulation, this post delves into its strategic applications for optimizing critical shipyard operations. We’ll show how it tackles specific challenges, from automated laydown planning and enhanced space utilization to efficient resource allocation and powerful what-if analysis. Discover how Plant Simulation helps identify and eliminate bottlenecks, accelerating delivery times and optimizing supply chain logistics for greater efficiency and predictability.

Siemens Tecnomatix Plant Simulation offers a comprehensive toolkit for addressing specific shipbuilding challenges, optimizing various critical aspects of shipyard operations.

Automated Laydown Planning and Block Placement Optimization

Shipyards face limited space and the challenge of managing large, irregularly shaped blocks. Plant Simulation optimizes material flow, resource, and space utilization, from cutting to final ship assembly. It allows planners to test machinery positions and material flow, minimizing movements before physical installation, and provides visual scheduling results for block layouts and progress.

Enhanced Space Utilization with Plant Simulation

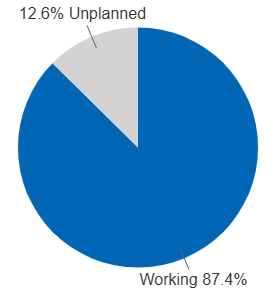

Simulation optimizes laydown strategies, increasing productive space usage to 87%, compared to only 70–75% in traditional planning – minimizing wasted space and maximizing efficiency.

Resource Allocation and Utilization

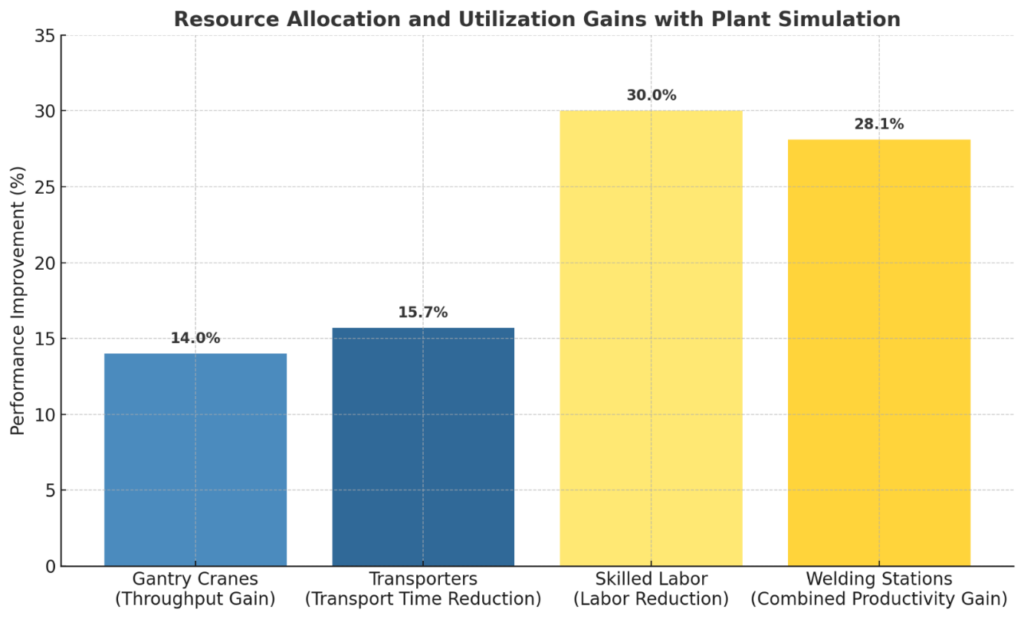

Effective management of equipment and resources (laborers, cranes, transporters) is crucial. Plant Simulation provides computer-supported answers for resource deployment, optimizing material flow and resource utilization across all planning levels. It models shift calendars and provides clear insights for complex processes, predicting utilization in each project area to maximize resource use and capacity.

Impact of Plant Simulation on Key Shipyard Resources

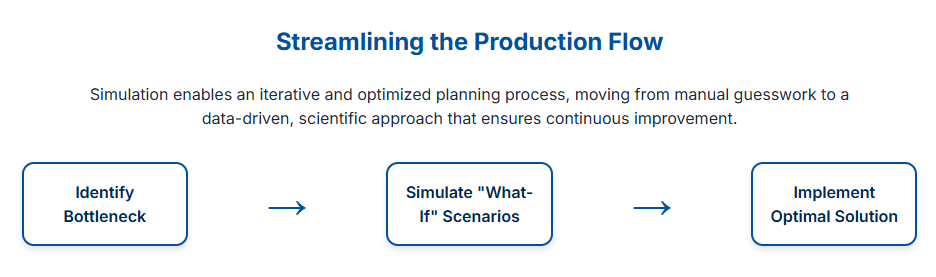

What-if Analysis and Production Planning

Shipbuilding’s complex and dynamic conditions make assessing changes difficult without disrupting operations. Plant Simulation enables extensive “what-if” scenario analysis without disturbing existing systems, or long before new systems are installed. This allows shipyards to:

Bottleneck Identification and Delivery Acceleration

Bottlenecks limit overall production capacity and delay project timeline. Plant Simulation provides powerful tools for detection and analysis:

Supply Chain and Logistics Optimization

Efficient logistics and supply chain management are critical for moving vast quantities of materials. Plant Simulation models and analyzes material flow from raw material arrival to final ship delivery. It helps:

Streamlined Production Flow

Now that you’ve seen the strategic uses, in our next blog, we present the tangible impact and measurable benefits this powerful simulation technology delivers.

Join us this July for our exclusive webinar on Shipyard Optimization using Tecnomatix Plant Simulation.

Fill out the registration form to save your spot – Register Now