Unleash the potential of DYNMIK Design Die – Motion Simulation with us if you struggle with any of the following challenges:

Having difficulty with verification of your creative and unique mechanisms for handling complicated parts

Costly design errors during assembly or during the trial period

Having a hard time explaining design details to your customers during the design review stage

Your customer does not always have experience understanding your design concepts

Finding a quick way of training your newly hired designers to help understand die design applications

Your design lead time is extended by having to rely on a third party for handling die transfer system designs

Finding a way to optimize designs for increasing Strokes per Minute (SPM), especially for transfer die applications

Register to the webinar now to understand how DYNMIK Design Die application helps overcome these common industry challenges!

Whether you are already using DYNMIK or hearing about it for the first time, this webinar is for all. It is a good opportunity for everyone to explore its capabilities and the overall process.

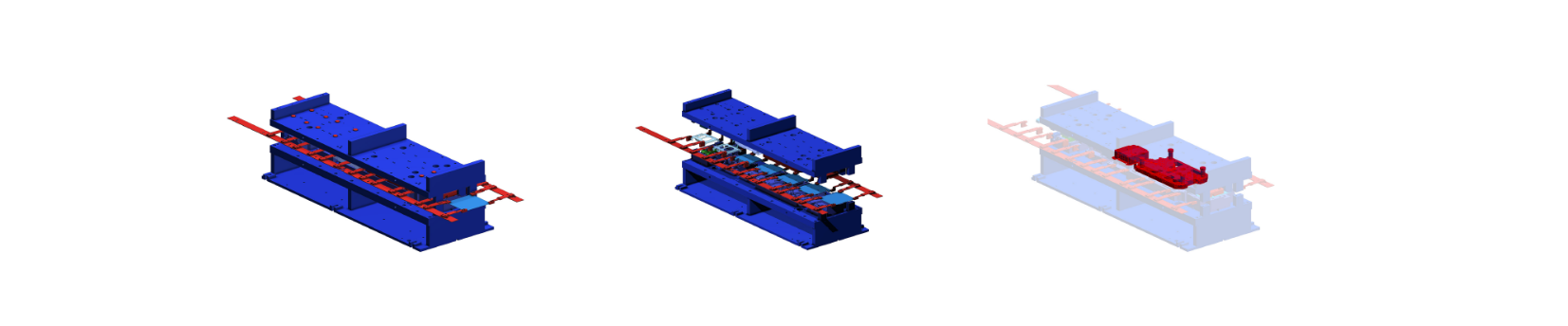

We will illustrate how this state-of-the-art solution provides a user-friendly interface for simulating motion and interaction of individual mechanisms or complete die systems. It helps save time and money, verify design feasibility and achieve desired production results.

This application offers many outstanding benefits in the die industry such as:

Easy-to-use interface requires limited training

Verify complex mechanisms for handling complicated parts

Get accurate press setting parameters for your production

Analyze velocity and acceleration of tools and transfer systems

Perform all tasks within Siemens NX™

Determine and optimize Strokes per Minute (SPM) to meet customer requirements

Check designs for potential interference conditions to avoid costly damage caused by collisions

Dynamically present verified designs to customers with motion animation, simulating a complete production cycle