Keys to Success

Leveraging Dynmik Design for Mold Software

Using advanced collision-checking, motion simulation

Commitment to quality and continuous improvement

Challenges

Reducing number of design errors detected on the shop floor

Reducing lead time for design validation, delivery

Increasing confidence in the design validation process

Validation of increasingly complex designs

Results

85% reduction in time spent validating mold designs

Significant decrease in design errors

Significant increase in accuracy of validation results

Increased on-time delivery

Increased quality assurance

About Redoe

Redoe Group is a world-class global mold manufacturer specializing in surface critical, multi–color/material and optical injection molds. The company’s state-of-the-art manufacturing sites and technical centers are located throughout North America and Asia. The Redoe Group is well positioned to provide solutions for its customers with global automotive vehicle platforms, as the group operates the same technologies and equipment types at each of its regional production facilities.

By combining the latest engineering and manufacturing techniques, Redoe develops high-quality tooling capable of delivering precision components required by its customers. Through over 50 years of experience, the group has established a solid reputation for our quality and customer service.

The Challenge

When it came to validating its mold designs, Redoe was being limited by the capabilities of existing software to provide quick and accurate analysis of its designs. Using existing solutions and approaches, it was taking experienced designers nearly two hours to validate to complete a check of a typical design. With growing pressure from customers for shorter lead time and more complex designs, Redoe turned to the Dynmik Design for Mold solution offered by Longterm Technology Services.

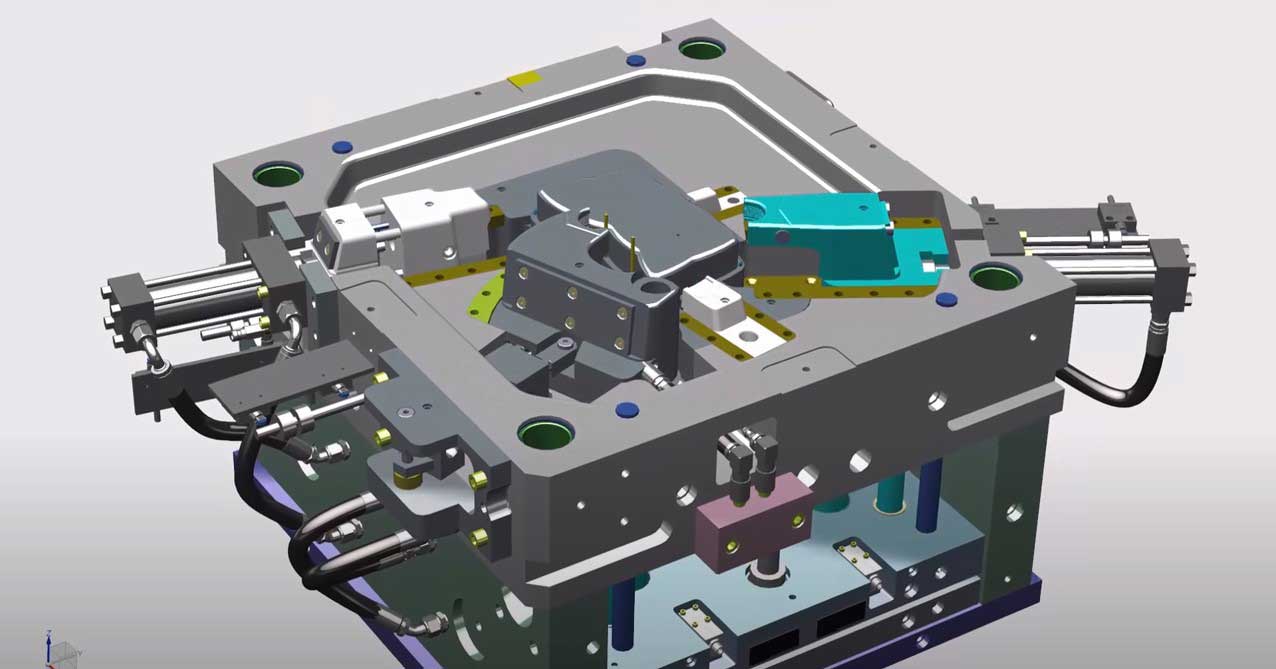

Dynmik Design for Mold is a software add-on for the NX Mold Wizard solution, a part of the Siemens NX CAD family of products. This software is used to perform motion simulation and collision checking to allow mold designers to quickly and accurately validate their designs before sending to the shop floor.

The Solution

With the adoption of Dynmik Design for Mold, however, Redoe was able to accomplish its design validation in 12-15 minutes. It could do so without ever leaving the NX CAD UI, and better yet, it was able to achieve increased accuracy in its validation results.

“With this software, one person can very accurately verify many molds in the short amount of time, especially compared to our previous methods,” says Richard Vegh, Senior Mold Designer at Redoe Mold. “My first time using the software. I was able to complete check of 4 slides and 2 slides travel on angle. Lifters and ejection, core, cavity components and the LH and RH customer data. Time to complete was almost 2 hours. Now I start with same job and can complete in 12-15 minutes. Very user friendly and easy to learn.”

“This product will speed up the design checking and also prevent mistakes,” adds Richard Vegh. “Most of the previous checking was done for pocketing to one-half of the mold. Also, many of the other current dynamic checking procedures do not catch the very small details that can be a problem. Dynmik checks everything. I’m currently learning to use this product and find the software very intuitive and user friendly to learn.“

With its latest release, Dynmik Design now has a host of new features that Longterm Technology Services has introduced in direct response to demand from the moldmaking industry. These features include:

Collision Checking & Minimum Clearance

This is a new one-of-a-kind interface that allows designers to quickly identify potential interference conditions. The results for the entire cycle are listed together for analysis, and users can specify minimum clearance values to maintain a safety zone around components. They can also export current motion simulation steps for further analysis.

0.1 Motion Simulation Increment

Users can now use 10x more precise motion steps when simulating (in NX 1926 and above versions) to verify even more complex and high-precision motions.

Tracking Curve

This feature offers a quicker way to verify a component’s clearance areas by visualizing its motion curves around other components.

Copy Component

This feature allows you to duplicate existing defined components with all motion parameters and define different geometries. This helps divide components with a large number of geometries into smaller segments for receiving more manageable collision-checking results downstream.

“I am very impressed with your analysis software DYNMIK Design Mold software,” adds Vegh. “I like the way it checks dynamic and static interference no matter how small they may be. I’m recommending all of the Tool designs have this analysis done before any manufacturing is done.“

Moving Forward

Using Dynmik Design for Mold, Redoe is poised to press onward with its proven commitment to continuous improvement. The company is positioned to provide higher-quality, more complex molds with shorter lead times than ever before, and its customers are noticing.

If you’d like to learn more about Dynmik Design for Mold or set up a demo for you and your team, please don’t hesitate to reach out to us today.