Introduction: Navigating the Complexities of Modern Shipyard Building

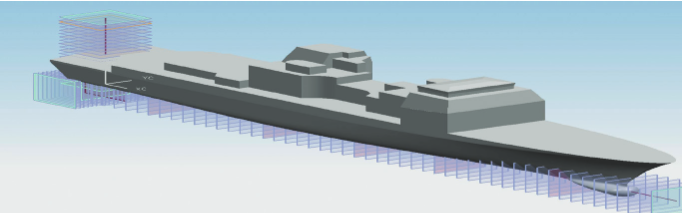

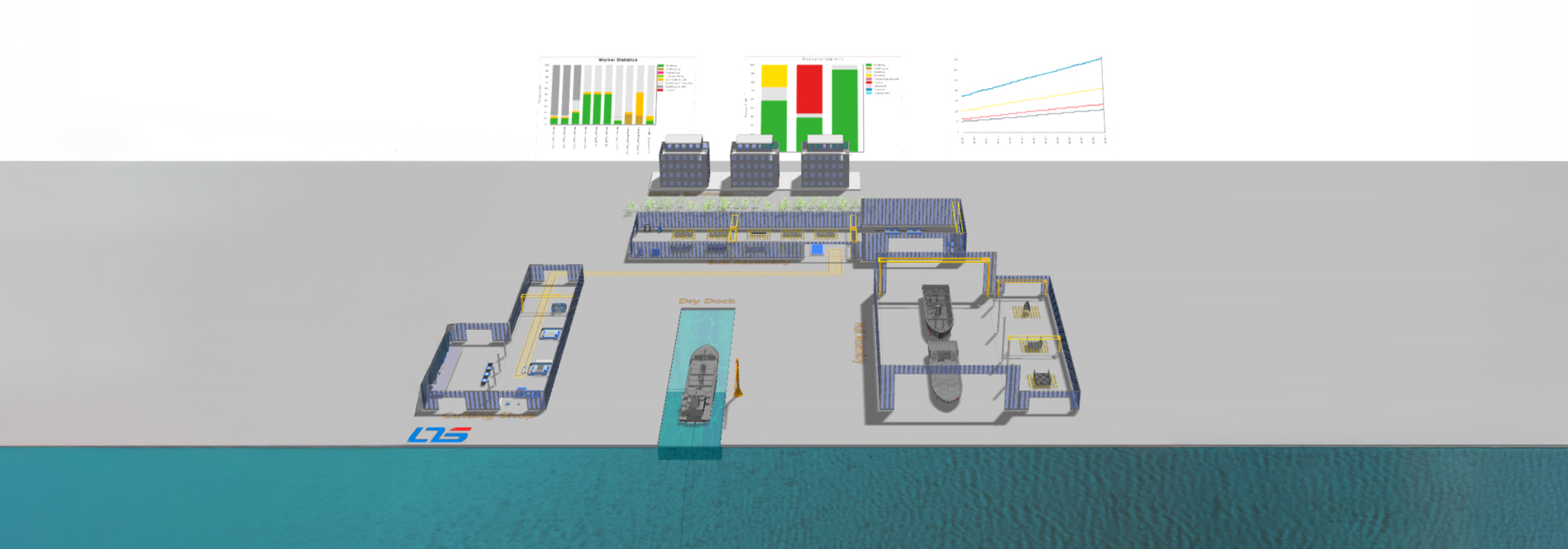

Modern shipbuilding is a complex manufacturing process, characterized by custom vessels and pressure to enhance efficiency, reduce costs, and accelerate delivery times. Traditional planning methods often fail to address the dynamic nature of shipyard operations, where large assemblies remain stationary, and resources move around them. This complexity makes material flow, resource allocation, and scheduling challenging, leading to inefficiencies and delays. An efficient shipyard layout is crucial for operational success, influencing productivity, quality, and safety. Simulation has emerged as an indispensable tool, enabling shipyards to model, analyze, and optimize their production environments virtually, increasing planning reliability and reducing work-in-progress. This digital transformation is vital for long-term competitiveness and resilience in a volatile market.

Key Considerations in Shipyard Layout Optimization for Operational Efficiency

Optimizing a shipyard layout requires a holistic approach, considering interconnected factors:

Tecnomatix Plant Simulation: Capabilities and Tools for Layout Optimization

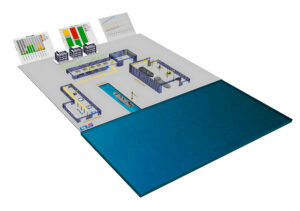

Tecnomatix Plant Simulation, a Siemens Digital Industries Software product, is a discrete event simulation (DES) tool for modeling, simulating, analyzing, visualizing, and optimizing complex production systems. Its object-oriented architecture allows for hierarchical 3D models, enabling rapid creation and maintenance of complex simulations. This allows for “what-if” scenarios in a virtual environment, reducing investment risks.

Plant Simulation offers tools for diagnosing inefficiencies:

Customizable Objects: Tailoring Simulation to Shipbuilding Workflows

Plant Simulation’s strength lies in its customizable objects, allowing precise tailoring to shipbuilding’s unique processes. Users can develop reusable custom library elements, defining complex material flow rules. Specialized toolkits minimize modeling effort.

Plant Simulation can model diverse shipbuilding operations:

This detailed modeling facilitates virtual commissioning of the entire shipyard, validating production processes before physical work begins.

Seamless Integration with Siemens PLM Ecosystem for Data-Driven Decisions

Plant Simulation’s integration with the Siemens PLM ecosystem, particularly Teamcenter, enhances collaboration and drives informed decision-making. Teamcenter acts as a centralized data backbone, connecting engineering, manufacturing, and logistics. Plant Simulation allows direct import of external CAD data. Integration with Siemens tools creates a digital twin of manufacturing processes. This virtual replica enables dynamic simulation and validation of manufacturing plans early in the lifecycle.

Conclusion: Charting a Course for Future-Ready Shipyards

Tecnomatix Plant Simulation is a pivotal technology for modern shipyards, offering a comprehensive approach to optimizing operations. It enables meticulous layout optimization, streamlines material flows, maximizes space and resource utilization, and provides a robust framework for future growth. Its specialized tools and customizable objects offer deep analytical capabilities. Amplified by its seamless integration within the Siemens PLM ecosystem, Plant Simulation fosters a true digital twin environment. This proactive approach drastically reduces costly errors, minimizes rework, and accelerates time-to-market. Adopting Tecnomatix Plant Simulation is a strategic imperative for shipyards seeking to remain competitive and resilient, ensuring they are future-ready.