In manufacturing, production scheduling is the heartbeat of operations. It coordinates resources, materials, and workflows to meet customer demand on time. Yet, many companies – from small firms to global enterprises – still rely on spreadsheets for scheduling. While this approach seems simple and familiar, it hides serious costs and risks that erode productivity and profitability.

Siemens Opcenter APS (Advanced Planning and Scheduling), replaces spreadsheet-based planning with intelligent, integrated scheduling.

The result?

Faster, more accurate decisions, optimized resources, and measurable returns. Let’s uncover the hidden costs of manual scheduling – and why Opcenter APS is a game changer.

The Hidden Costs of Spreadsheet Scheduling

While spreadsheets are flexible, they come with vulnerabilities that undermine manufacturing performance.

Siemens Opcenter APS: A Smarter Approach to Scheduling

What It Is

Siemens Opcenter APS is a suite of production planning and scheduling tools powered by advanced algorithms. It synchronizes manufacturing processes to balance demand and capacity while honoring real-world constraints. The software doesn’t just speed up scheduling – it finds the optimized schedule for efficiency and delivery performance.

It’s industry-agnostic, supporting sectors from aerospace to food manufacturing, and scales from SMBs to global enterprises.

Key Capabilities

Opcenter APS empowers manufacturers with advanced features designed to optimize scheduling, resource allocation, and operational efficiency

- Order-Based Multi-Constraint Scheduling – Schedules account for machine availability, material readiness, changeover times, and production speeds. This ensures realistic, executable plans.

- Advanced Material & Resource Modeling – Supports complex BOMs, make-to-order/make-to-stock strategies, and exports purchase requirements directly to ERP.

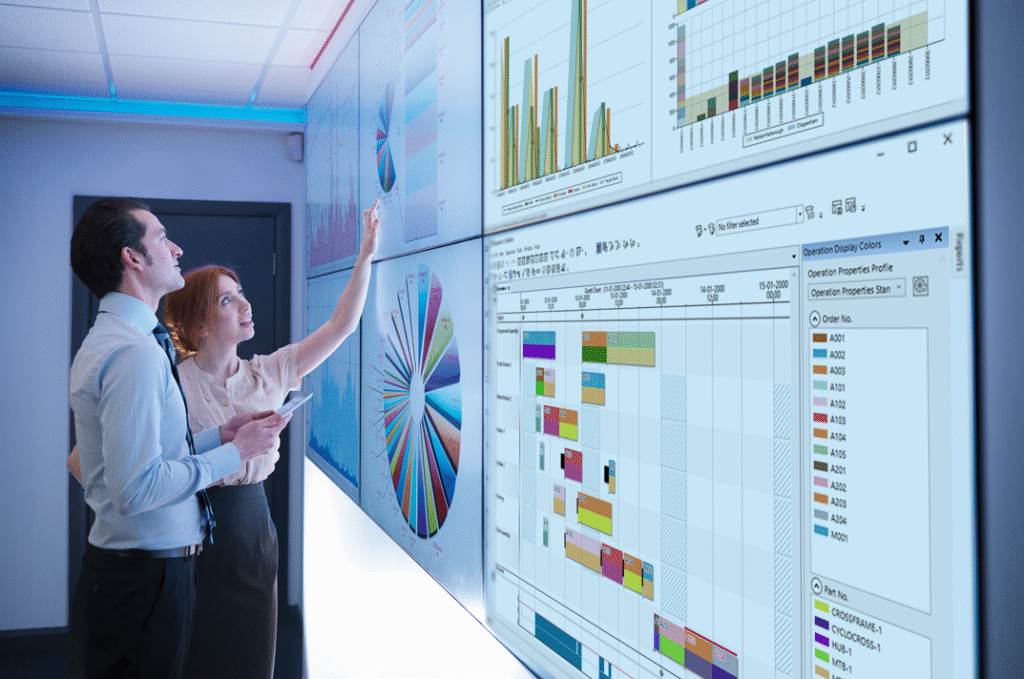

- Interactive Visualization & “What-If” Analysis – Digital twins of the production floor allow planners to simulate changes before committing. Material Explorer forecasts shortages and inventory issues in advance.

- Seamless Integration – A full API links APS with ERP, MES, and other enterprise systems, enabling a single, transparent view of operations.

- Scalability – Modular architecture fits both small teams and global plants.

Table: Spreadsheet Scheduling vs. Siemens Opcenter APS

Hidden Cost Category | Spreadsheet-Based Scheduling | Siemens Opcenter APS |

Knowledge Management | Dependent on individuals; no formal documentation. | Centralized data repository; codified rules; preserves institutional knowledge. |

Operational Efficiency | Manual errors; bottlenecks; high idle time. | Algorithm-driven optimization; reduced lead/cycle times. |

Data Integrity & Visibility | Corruptible files; hidden formulas; poor auditability. | Real-time ERP/MES integration; transparent production modeling. |

Agility & Responsiveness | Difficult “what-if” analysis; slow to adapt. | Scenario planning; dynamic scheduling; rapid adjustments. |

Financial Impact | Higher costs; poor on-time delivery; lower competitiveness. | Reduced WIP/inventory; higher productivity; improved service levels. |

Tangible Benefits and ROI

Implementing Opcenter APS delivers measurable results, improving efficiency, reducing costs, and boosting overall manufacturing performance

- Efficiency Gains

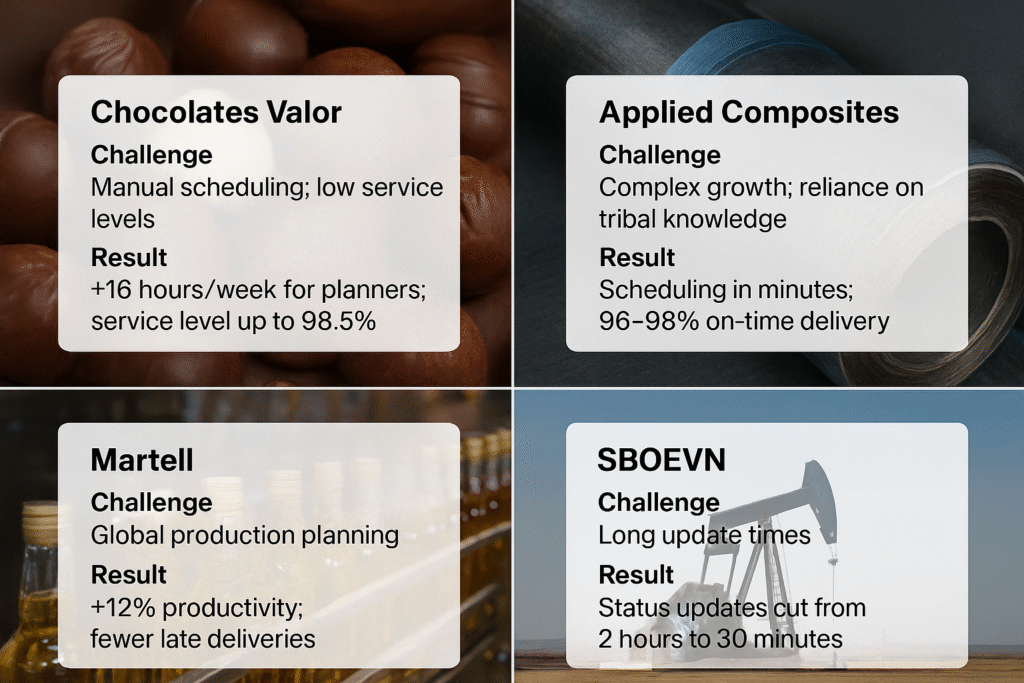

Across industries such as aerospace composites, food manufacturing, beverage production, and oilfield equipment, organizations have achieved faster scheduling, reduced planning effort, higher productivity, and quicker production status updates. It enables more agile decision-making and improved coordination between departments. - Cost Reduction

Optimized scheduling reduces WIP and inventory by up to 50%, freeing capital and cutting waste.

Source – Siemens Digital Industries Software

Source – Siemens Digital Industries Software

- On-Time Delivery

Customers see up to an 80% improvement in delivery performance. Applied Composites achieved 96–98% on-time rates even amid COVID-era supply shortages. - Better Decisions

Real-time data and predictive insights empower proactive management and fast responses to market opportunities.

Case Study Highlights

Opcenter APS has demonstrated its ability to deliver measurable efficiency improvements across diverse industrial sectors worldwide.

Real-world examples of efficiency gains achieved with Opcenter APS.

Real-world examples of efficiency gains achieved with Opcenter APS.

The Bottom Line

Spreadsheet scheduling quietly drains time, money, and agility from manufacturing operations. Siemens Opcenter APS replaces that fragility with a centralized, intelligent, and integrated planning environment.

By moving to Opcenter APS, manufacturers can expect faster scheduling, lower costs, better on-time performance, and stronger decision-making – all of which translate to a direct competitive advantage.

For manufacturing leaders, the choice is clear: stay bound by the hidden costs of spreadsheets, or adopt APS to unlock operational excellence and position your business for long-term growth.