The shipbuilding industry, a crucial pillar of global commerce and national defense, faces significant hurdles like declining capacity, aging infrastructure, and persistent labor shortages. Traditional planning methods often fall short, leading to inefficiencies and cost overruns.

This blog post series shows Siemens Tecnomatix Plant Simulation as a transformative solution for modern shipyards. By harnessing its advanced features, such as:

Shipyards can create dynamic virtual environments to rigorously test, validate, and optimize production processes. This digital approach promises:

Ultimately, it empowers shipbuilders to navigate complexity with precision and secure a competitive advantage in a demanding global market.

In our first blog post, we will explore how Plant Simulation’s advanced features, like discrete event simulation and comprehensive analysis tools, enable shipyards to create dynamic virtual environments. This digital approach promises unparalleled operational efficiency, significant cost savings, and enhanced strategic agility, empowering shipbuilders to navigate complexity and secure a competitive advantage.

Navigating Complexity in Modern Shipbuilding

Today’s shipbuilding industry operates in an intricate and challenging landscape. The immense scale of constructing custom vessels, combined with the dynamic interplay of countless components and skilled labor, creates substantial complexities. These inherent challenges are exacerbated by external pressures and systemic inefficiencies that demand a new approach to planning and scheduling.

Key Challenges:

These interconnected issues highlight the urgent need for an integrated approach that can model and optimize the entire shipbuilding ecosystem.

Siemens Tecnomatix Plant Simulation: The Digital Backbone

Addressing the multifaceted challenges in shipbuilding requires a robust analytical framework. Siemens Tecnomatix Plant Simulation, a leading discrete event simulation (DES) software, offers a powerful methodology to model, analyze, and optimize intricate shipyard systems.

Principles of Discrete Event Simulation (DES)

DES models a system’s operation as a sequence of discrete events, where changes occur only at specific points in time. This approach is ideal for complex processes with distinct interactions. Key components include:

Core Capabilities of Tecnomatix Plant Simulation

Below are some of its core capabilities that make it an industry-leading solution:

The Virtual Shipyard and Digital Twin Concept

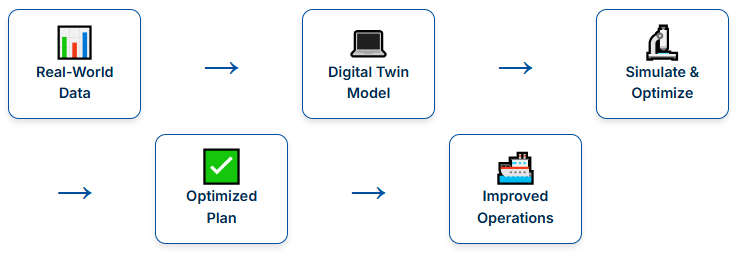

Plant Simulation is central to the “Virtual Shipyard” and “Digital Twin” concepts. This involves creating a comprehensive digital replica of a physical facility, integrating real-time data for dynamic modeling. A virtual shipyard provides decision-makers with a dynamic model of operations, allowing them to test scenarios like layout adjustments, material flow modifications, and production schedule revisions using live project data. This empowers shipbuilders to optimize yard layout, predict ROI for proposed changes, and adopt innovative technologies.

The Digital Twin Process Flow

Ready to see how digital simulation transforms shipyard operations? In our next blog, we’ll dive into the strategic applications that optimize every aspect of shipbuilding.

Join us this July for our exclusive webinar on Shipyard Optimization using Tecnomatix Plant Simulation.

Fill out the registration form to save your spot – Register Now